Metiz-Prom is an industrial enterprise in the Republic of Kazakhstan, producing a wide range of wares from metal, plastic, and composite materials.

The company uses automated lines in production. Almost all equipment is program-controlled (CNC) and operates and produces wares without human intervention.

Equipment requires continuous maintenance and optimization, which is why Metiz-Prom always tries to find the best way to:

- optimize equipment maintenance and management processes;

- automate logistic operations.

The use of a human resource for these tasks did not justify itself, and the best solution was to implement software.

Aleksey Bazhin, CEO of the company, said that while trying to launch such software, the company faced some common issues:

- high development costs;

- a long process of selecting and hiring a development team;

- constant changes in the equipment that cause corresponding API changes.

The last is the key to connecting systems.

Goals

The software should remove the need to expand the engineering team, speed up equipment maintenance processes, and enable constant line monitoring.

The team had to accomplish several goals:

- create a notification system for emergencies on production lines;

- optimize the processes of storage and purchase of supplies.

Solution

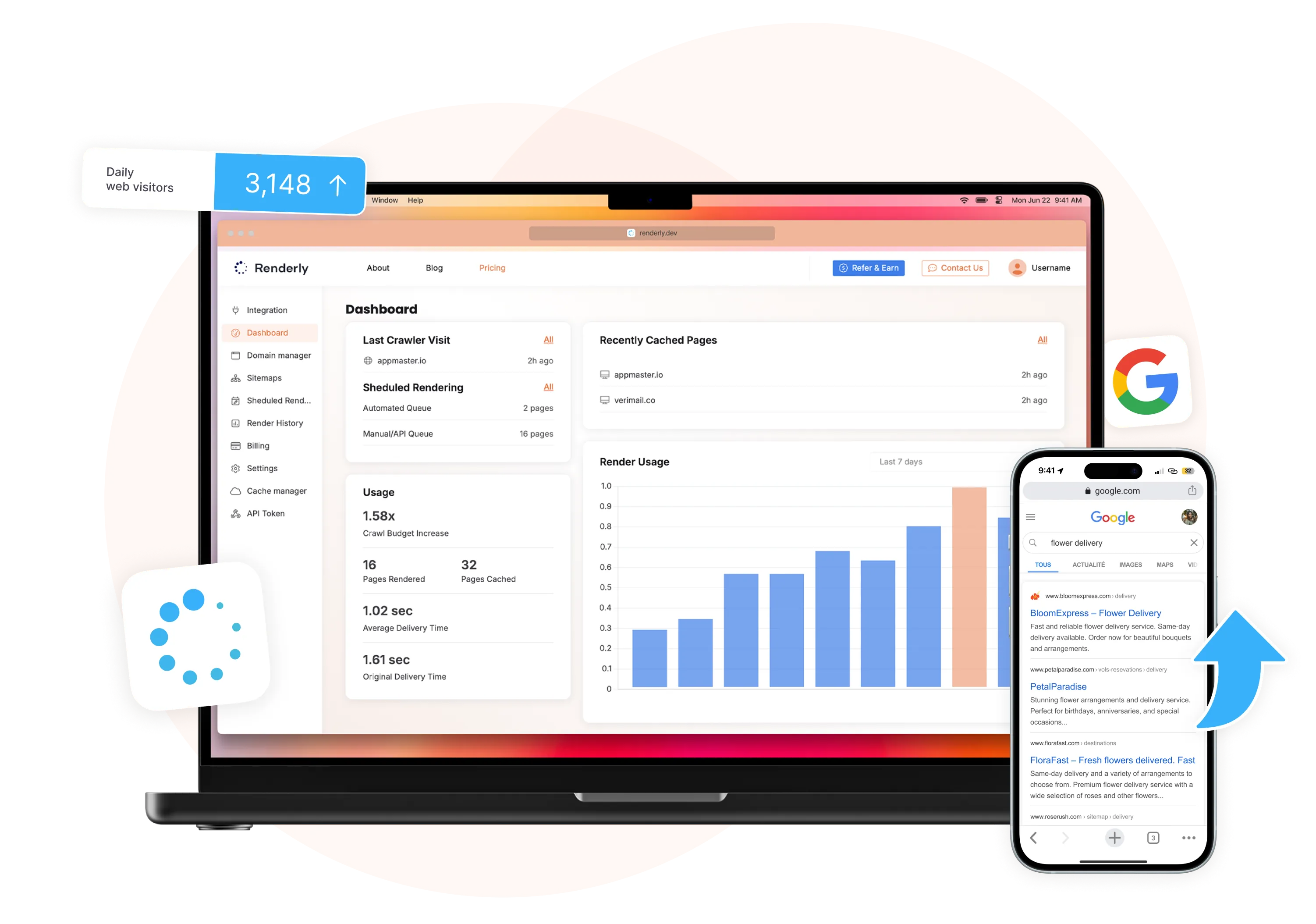

As a solution for Metiz-Prom's query, on the AppMaster.io platform, we built a server application to monitor and maintain the production lines of an enterprise. We also created a service for automated ordering of consumables from warehouses and forecasting the need for materials.

Server application

The application works as follows: the production line equipment transmits telemetry to the application in real-time. In other words the application makes remote measurements and collects information provided by the lines.

Part of the line equipment was configured to send data to the webhook address of the server application. The other part transmitted telemetry through requests to the API of this equipment.

Metiz-Prom was the first project where the updated application endpoints on AppMaster.io were used, which support XML format, and WebSockets (WSS) when connected to industrial equipment.

The load's requirements and restrictions caused some difficulties, but we managed to overcome the issue by hosting the server application on enterprise servers in isolated containers in cluster mode.

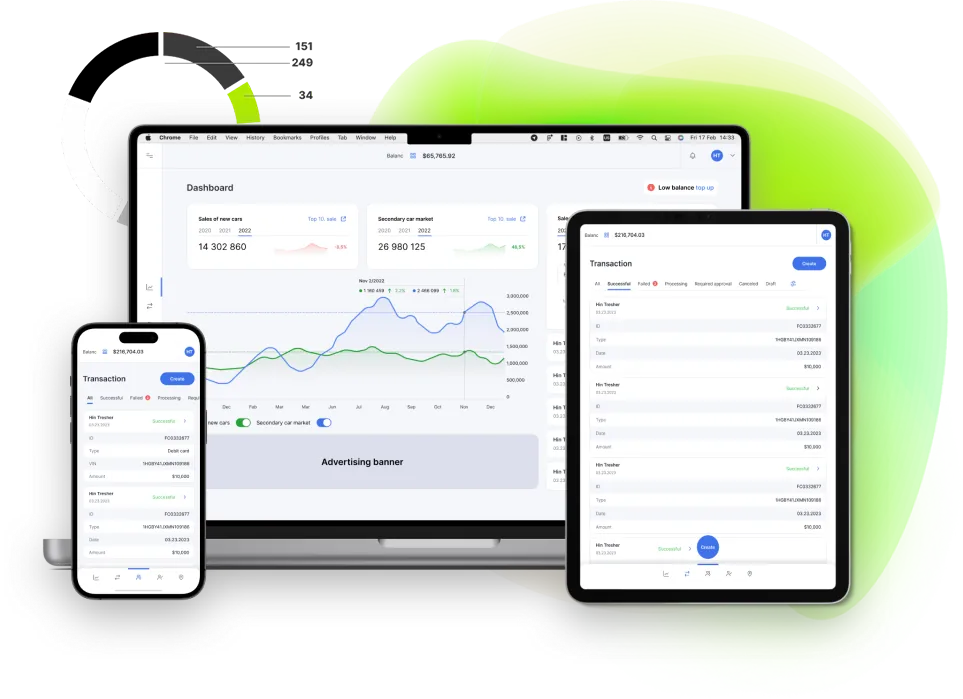

Monitoring system

Another important task was to create a system for monitoring the condition of the equipment, so it would be possible to systematically and quickly perform maintenance, monitor the remaining consumables, and replenish warehouses on time.

To do this, we created a panel that displayed the status of all production line components and the remaining resource of consumables. The panel provides access to information about the status of technical processes, line errors, and important notifications and forecast the need for equipment maintenance.

The system estimates the materials consumption considering previous periods, focusing on the number of operations performed for processing products and their types. Plus, it allows reviewing old data with trends for a certain period of time.

Notification system

To provide timely notifications about emergencies on the lines and the upcoming need to replenish supplies, we created a notification system operating via Telegram bot. So the team could get instant messages whenever an emergency occurred.

Implementing such functionality is quite simple on AppMaster.io due to the built-in modules and the ease of integrating third-party services with the platform.

Results

After implementing the server application, the company managed to reduce the risks of production lines being interrupted. They optimized the processes of purchasing and storing spare consumables significantly. As a result, supplies did not accumulate, and deliveries for production arrived on time without delaying work.

The team began to receive notifications of emergencies in real-time. In addition, the need to expand the staff of service engineers and on-duty personnel has been reduced.

Components: backend, web application, Telegram module, web hooks, web sockets, application cluster.