All You Need To Know About Machine Learning in Predictive Maintenance Software Architecture

Discover how machine learning in predictive maintenance software architecture impacts your business.

Predictive maintenance is a proactive maintenance strategy that aims to predict when equipment will require maintenance based on gathered data from various sources, such as sensors, historical information, and external factors. The main goal of predictive maintenance is to minimize equipment downtime and avoid costly repairs and production losses that occur due to unexpected equipment failure. In traditional maintenance approaches, equipment maintenance schedules are determined by historical information, which may not accurately reflect current conditions or be suitable for new or updated systems.

With the advent of the Internet of Things (IoT) and advanced data analysis techniques, predictive maintenance has become increasingly feasible and effective. Machine learning, a subset of artificial intelligence, has emerged as a crucial tool in developing predictive maintenance software. Machine learning algorithms enable computers to analyze large volumes of data, identify patterns, and make predictions without the need for explicit programming. By using machine learning in predictive maintenance software, companies can more accurately forecast equipment failures, optimize maintenance schedules, and extend the lifespan of critical assets.

The Crucial Role of Machine Learning in Predictive Maintenance

Machine learning is vital in predictive maintenance software architecture by automating failure prediction and maintenance recommendation processes. By leveraging machine learning algorithms, predictive maintenance software can analyze data gathered from various sensors and historical data sources, identify patterns, and make accurate predictions. This analysis reveals crucial insights for optimizing maintenance schedules and enhancing equipment performance. The primary benefits of incorporating machine learning in predictive maintenance software include:

- Improved predictive accuracy: Machine learning algorithms can process massive amounts of data and generate more accurate forecasts of equipment failures than traditional methods, leading to a more efficient maintenance strategy.

- Anomaly detection: Machine learning can detect unusual patterns in equipment performance data, allowing maintenance teams to identify potential issues before they become critical faults.

- Optimized maintenance schedules: Based on the insights from machine learning algorithms, maintenance teams can modify maintenance schedules to maximize equipment uptime and reduce costs.

- Enhanced decision-making: Machine learning insights enable more informed decisions by providing data-driven recommendations to maintenance teams, reducing the potential for human error.

Therefore, integrating machine learning techniques into predictive maintenance software has become essential in improving the efficiency of maintenance operations across a wide range of industries.

Key Machine Learning Algorithms for Predictive Maintenance

Several machine learning algorithms can be employed in predictive maintenance software to analyze data and make accurate predictions. Below are some of the key machine learning algorithms used to develop successful predictive maintenance solutions:

- Linear regression: Linear regression is a fundamental machine learning algorithm used to model the relationship between input features and a continuous output variable. In predictive maintenance applications, linear regression can be used to estimate the remaining useful life (RUL) of equipment based on sensor data and historical equipment failure information.

- Decision trees: Decision trees are a type of algorithm that can learn to make decisions by splitting input data into subsets based on specific conditions. These algorithms can be used to predict equipment failure by examining a range of factors, such as sensor readings, operating conditions, and maintenance history.

- Support vector machines (SVMs): Support vector machines are a class of algorithms used for classification and regression tasks. SVMs determine a decision boundary that separates data points into different classes, making them suitable for predicting whether a specific piece of equipment will experience a failure during a given time frame.

- K-means clustering: K-means clustering is an unsupervised machine learning algorithm used for grouping data points based on their similarities. In predictive maintenance, k-means clustering can assist in identifying groups of equipment that exhibit similar behavior patterns, enabling more accurate predictions and identification of anomalies.

- Deep learning neural networks: Deep learning neural networks are advanced machine learning algorithms that can learn complex patterns in large datasets. Neural networks can be particularly useful in predictive maintenance applications with vast amounts of sensor data for analysis. Convolutional neural networks (CNNs), recurrent neural networks (RNNs), and long short-term memory (LSTM) networks are examples of deep learning algorithms that can be used for predictive maintenance tasks.

The choice of machine learning algorithms for a specific predictive maintenance application will depend on factors such as the type and volume of data available, the desired level of prediction accuracy, and the computational resources needed for training and deployment.

Techniques for Implementing Machine Learning in Predictive Maintenance Software

Implementing machine learning in predictive maintenance software requires a structured approach encompassing data collection, preprocessing, feature extraction, algorithm selection, validation, and deployment. Here's an overview of each step in the process:

- Data collection: The foundation for implementing machine learning in predictive maintenance software is collecting data from various sources such as equipment sensors, maintenance records, and operational information. This data can be time-series, structured, or unstructured and it plays a vital role in building accurate machine learning models.

- Data preprocessing: Raw data collected from different sources might contain inconsistencies, missing values, and noise. Data preprocessing involves cleaning, normalizing, and transforming raw data into a format suitable for machine learning algorithms. This step enhances the quality of the input data, improving the performance of the machine learning model.

- Feature extraction and selection: Features are the attributes or properties of data that influence the predictive capabilities of machine learning algorithms. Feature extraction involves extracting meaningful features from the preprocessed data, while feature selection focuses on identifying the most relevant features. These features help reduce the complexity of machine learning models and improve their performance.

- Algorithm selection: Choosing the right machine learning algorithm for predictive maintenance depends on factors like data type, the complexity of the problem, and the desired level of accuracy. Commonly used algorithms in predictive maintenance include linear regression, decision trees, support vector machines, k-means clustering, and deep learning neural networks. Evaluating multiple algorithms is essential to identify the one that best suits your specific use case.

- Model training and validation: Once an algorithm is selected, the machine learning model is trained on a dataset derived from the preprocessed input data. The model's performance is then validated using a separate dataset, with cross-validation techniques to reduce overfitting. Performance metrics like accuracy, precision, recall, and F1 score are used to gauge the model's effectiveness in predicting equipment failure.

- Deployment and monitoring: After the machine learning model is validated, it's integrated into the predictive maintenance software architecture and deployed in a production environment. Continuous monitoring and evaluation of the model's performance are vital to ensure its effectiveness in real-world scenarios. Depending on the results, you may need to retrain the model and update its parameters to accommodate operating conditions or equipment behavior changes over time.

Machine Learning in Predictive Maintenance for Different Industries

Predictive maintenance powered by machine learning applies to various industries, from manufacturing and energy to transportation and healthcare. Here are a few examples of how different industries can utilize machine learning for predictive maintenance:

- Manufacturing: Machine learning in predictive maintenance can analyze data from sensors and equipment logs to detect anomalies and patterns in operational performance. This helps identify wear and tear in equipment, assess the remaining useful life (RUL) of assets, and recommend optimal maintenance schedules to avoid unexpected downtime.

- Energy and Utilities: The energy sector can monitor components like turbines, transformers, and pumps using machine learning algorithms to anticipate equipment failures and avoid costly shutdowns. For instance, wind farms can analyze data from multiple sensors to identify performance degradation in wind turbines and recommend maintenance activities before major issues arise.

- Transportation: In the transportation sector, machine learning can be used to analyze data coming from vehicles, public transit systems, and infrastructure to predict equipment failures and optimize maintenance schedules. For instance, airlines can gather data from sensors throughout their fleet to predict component failures, reducing flight delays and improving safety.

- Healthcare: In healthcare, machine learning models can analyze data from medical equipment like MRI machines, ventilators, and centrifuges to predict maintenance needs and prevent unexpected failures. Predictive maintenance can enhance patient care and reduce equipment downtime by delivering timely diagnoses and treatment.

Benefits and Challenges of Machine Learning in Predictive Maintenance

Implementing machine learning in predictive maintenance offers significant benefits but presents some challenges. Understanding both the advantages and potential pitfalls of incorporating machine learning in your predictive maintenance software architecture is essential.

Benefits

- Improved equipment performance: Machine learning models enable predictive maintenance software to identify patterns and anomalies in equipment data, detecting signs of equipment failure before it occurs. This allows maintenance teams to address issues before they lead to costly downtime or catastrophic failures.

- Reduced downtime and maintenance costs: Predictive maintenance powered by machine learning reduces unscheduled downtime by identifying potential equipment issues before they escalate. This proactive approach minimizes repair costs, extends equipment life, and optimizes maintenance resources.

- Increased energy efficiency: By monitoring equipment performance and identifying inefficiencies, machine learning can help facilities uncover opportunities to conserve energy and reduce operating costs.

- Enhanced decision-making: Machine learning models can provide valuable insights into equipment health, enabling better decision-making for maintenance tasks, resource allocation, and long-term planning.

Challenges

- Data collection and preprocessing: Collecting and preprocessing data from various sources can be complex and time-consuming. This process must be performed accurately to ensure the quality of input data and the effectiveness of the machine learning model.

- Algorithm selection and tuning: Selecting the right algorithm for predictive maintenance depends on multiple factors, and there's no one-size-fits-all solution. It might require testing various algorithms and parameter configurations to find the best-fit model for your specific use case.

- Data security and privacy: Ensuring the security and privacy of sensitive data collected from equipment sensors and logs is crucial to prevent unauthorized access or data breaches.

- Handling inaccuracies: Predictive maintenance models might not always accurately predict failures, resulting in false positives or negatives. This might lead to unnecessary maintenance activities or undetected equipment issues, requiring a balance between proactive and reactive maintenance strategies.

- Maintaining expert human involvement: Despite the advances in machine learning, human expert involvement is still essential in interpreting the results and making final decisions. As machine learning algorithms become more sophisticated, it's vital to maintain a balance between automation and human intervention.

When incorporated into predictive maintenance software architecture, machine learning provides significant benefits. By understanding the techniques, industry use cases, benefits, and challenges, you can make well-informed decisions when implementing machine learning in your predictive maintenance strategy. Leveraging no-code platforms like AppMaster can help you build scalable and secure predictive maintenance software solutions, enabling harnessing machine learning's full potential and maximizing your return on investment.

How No-Code Platforms like AppMaster Can Transform Predictive Maintenance Software Development

As the demand for predictive maintenance software continues to rise, businesses seek faster and more efficient ways to develop and deploy these solutions. Enter no-code platforms like AppMaster, which revolutionize the software development process and enable rapid, cost-effective development of predictive maintenance applications. In this section, we will discuss how no-code platforms like AppMaster can transform predictive maintenance software development by:

- Lowering the barrier to entry for businesses

- Accelerating the development process

- Flexibly integrating with existing systems and data sources

- Reducing technical debt

- Ensuring scalability and security

- Empowering citizen developers

Lowering the Barrier to Entry for Businesses

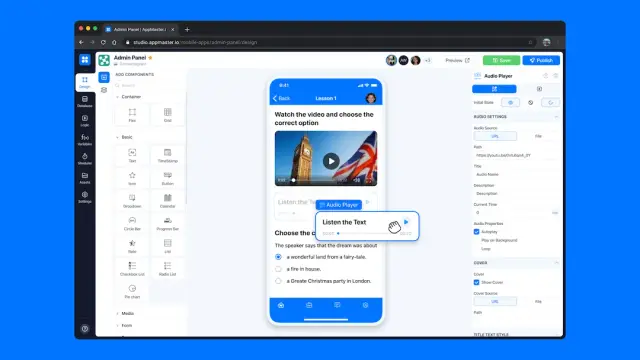

Traditionally, developing predictive maintenance software required a team of skilled developers and significant financial and time investments. No-code platforms like AppMaster eliminate this barrier, enabling a broader range of businesses to harness the power of predictive maintenance. By providing an intuitive drag-and-drop interface, AppMaster allows users to visually design their application without writing a single line of code. This drastically reduces the time and resources required to develop predictive maintenance software, making it accessible to businesses of all sizes.

Accelerating the Development Process

No-code platforms like AppMaster make developing predictive maintenance software easier and significantly accelerating the process. With comprehensive, integrated development environments (IDEs) available, users can quickly design data models, business processes, API endpoints, and user interfaces for web and mobile applications. Moreover, every time a user changes a project, AppMaster can generate a new set of applications in under 30 seconds while eliminating technical debt by regenerating applications from scratch.

Flexibly Integrating with Existing Systems and Data Sources

Predictive maintenance software relies on data from various sources such as IoT devices, sensors, and enterprise systems. No-code platforms like AppMaster allow users to seamlessly integrate with existing systems and data sources through REST APIs and other integration techniques. This enables organizations to leverage their existing infrastructure without requiring extensive redesign or re-engineering, simplifying the transition to a predictive maintenance approach.

Reducing Technical Debt

Technical debt can accumulate in traditional software development, leading to long-term challenges in maintaining and updating applications. No-code platforms like AppMaster address this problem by eliminating technical debt. By regenerating applications from scratch every time requirements are modified, AppMaster ensures that your software remains up-to-date and maintainable.

Ensuring Scalability and Security

Predictive maintenance software needs to scale with the organization's growth and handle high-performance use cases. AppMaster generates applications using powerful backend programming languages like Go (Golang) for amazing scalability and performance while harnessing the power of Vue3 framework (JS/TS) for web applications and Jetpack Compose (Android) and SwiftUI (iOS) for mobile applications. Moreover, AppMaster emphasizes security by allowing businesses to host their applications on-premises, ensuring that sensitive data is not exposed to third parties.

Empowering Citizen Developers

No-code platforms like AppMaster empower citizen developers by giving them the tools to create comprehensive and scalable software solutions without relying on a team of professional developers. By fostering a collaborative environment between IT teams and non-technical staff, no-code platforms democratize software development and foster innovation across all levels of an organization.

No-code platforms can potentially transform how businesses develop and deploy predictive maintenance software. As an American writer Larry Bossidy astutely observed, "Complexity has nothing to do with intelligence, simplicity does." By lowering the barrier to entry, accelerating the development process, enabling flexible integration, reducing technical debt, and empowering citizen developers, no-code solutions are poised to revolutionize the world of predictive maintenance and foster a new era of intelligent, data-driven decision-making.

FAQ

Predictive maintenance is a proactive maintenance strategy that identifies when equipment is likely to fail by analyzing data gathered from sensors, historical information, and other sources. The goal of predictive maintenance is to minimize downtime and avoid costly repairs before they occur.

Machine learning algorithms can analyze large volumes of data from sensors, historical information, and other sources to identify patterns and anomalies. By detecting early signs of equipment failure, machine learning enables predictive maintenance software to provide accurate predictions and recommendations for maintaining equipment.

Some common machine learning algorithms used in predictive maintenance include linear regression, decision trees, support vector machines, k-means clustering, and deep learning neural networks.

Benefits of using machine learning in predictive maintenance software include improved equipment performance, reduced downtime and maintenance costs, increased energy efficiency, and enhanced decision-making.

Challenges in implementing machine learning in predictive maintenance software include collecting and preprocessing data, selecting the right algorithms, ensuring data security, handling inaccuracies in predictions, and maintaining expert human involvement.

No-code platforms like AppMaster enable the rapid development of predictive maintenance software by allowing users to design backend, web, and mobile applications visually, along with the necessary data models, business processes, and API endpoints. The generated source code can be customized and integrated within existing systems to provide scalable and secure solutions for predictive maintenance applications.