Revolutionizing Supply Chain with Low-Code AI

Explore how low-code AI platforms are transforming the supply chain sector, offering agility, efficiency, and data-driven insights to businesses of all sizes. Learn about this symbiosis of technology and its impact on the industry.

Low-Code AI in the Supply Chain

The convergence of artificial intelligence (AI) and low-code development platforms is giving rise to an exhilarating paradigm in supply chain management. This innovative coupling, known as low-code AI, is redefining the playing field for businesses seeking efficiency and agility in their supply chain operations. By harnessing the power of AI without the intricacy traditionally associated with its adoption, low-code platforms are democratizing technology that was once the sole preserve of organizations with deep pockets and specialized personnel.

Low-code AI brings intelligent automation, real-time analytics, and visionary predictive capabilities within the reach of a vast range of businesses. It simplifies the integration of AI within supply chains, allowing companies to respond swiftly to changing market conditions, anticipate future demands, and solve complex logistical challenges with unprecedented ease. Through a visual development interface, users — regardless of their coding expertise — can create and deploy AI-driven solutions that monitor, analyze, and enhance various facets of the supply chain.

The transformative impact of low-code AI stretches across inventory management, procurement, logistics, and customer service. Companies leveraging this technology experience a marked enhancement in decision-making, operational transparency, and customer satisfaction. The significant reduction in development time and cost directly translates to a competitive edge and the ability to innovate continuously.

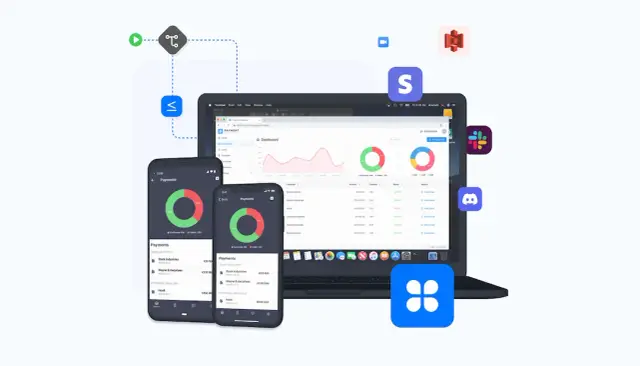

As we delve deeper into understanding low-code AI in the supply chain, it's essential to recognize platforms like AppMaster that empower businesses to create powerful software solutions. AppMaster's no-code environment allows users to generate applications that can intensely customize and optimize supply chain processes. This speeds up application development by a factor of 10 and does so at a fraction of the cost, enabling supply chain managers to rapidly adapt to new opportunities or challenges. The intersection of AI and low-code platforms is thus not just an incremental development; it is a monumental leap forward in managing supply chains effectively in an ever-dynamic market.

The Impact of AI on Supply Chain Management

The integration of Artificial Intelligence (AI) into supply chain management has brought forth groundbreaking changes, ushering in a new era of operational efficiency and strategic planning. AI's pervasive influence on the supply chain can be witnessed across various facets, from predictive analytics to automation and beyond.

Consider the profound impact of AI on demand forecasting. Traditional methods often relied on historical data and human intuition. AI infuses these forecasts with a degree of precision previously unattainable. By analyzing vast amounts of data — encompassing market trends, consumer behavior, and even socio-economic indicators — AI algorithms accurately predict future demand. This enables organizations to optimize their inventory levels, reducing both overstocking and stockouts, leading to significant cost savings and increased customer satisfaction.

AI's ability to automate complex decision-making processes has transformed inventory management, another critical aspect of the supply chain. Through the use of AI-powered tools, businesses can maintain optimal stock levels, anticipate replenishment needs, and even navigate the challenges of perishable goods with greater agility and less waste.

Logistics and transportation, the lifeblood of any supply chain, have similarly been enhanced by AI. Route optimization algorithms consider countless variables, such as traffic patterns, weather conditions, and vehicle capacity, to determine the most efficient paths for delivery. This optimization saves time and fuel costs and improves delivery reliability — a key competitive advantage in today’s market.

Supplier selection and management are other areas where AI shines. AI systems analyze supplier performance, compliance, and risk factors, enabling procurement teams to make data-driven decisions that align with company goals and values. This strategic alignment with the right partners fosters a powerful and resilient supply chain that weathers market volatilities.

Moreover, AI powers advanced customer service solutions, like chatbots and automated support systems, that provide timely and personalized responses to inquiries. This automation elevates the customer experience and allows human customer service representatives to focus on complex and high-value interactions.

Lastly, AI’s role in supply chain resilience cannot be overstated. By simulating various risk scenarios and their potential impacts, AI helps companies develop contingency plans that ensure business continuity in the face of disruptions. Whether it pertains to natural disasters, geopolitical tensions, or market fluctuations, AI-equipped supply chains can react swiftly and strategically to maintain operations.

AI's role in modernizing supply chain management is not just transformative; it's indispensable. Companies striving to remain competitive must embrace AI as a critical component of their supply chain strategy. The amalgamation of AI with supply chain processes is not a distant future — it is the present and redefining how businesses operate and thrive in an interconnected world.

Low-Code Platforms: Pioneers in Agile Supply Chain Solutions

As global markets grow increasingly dynamic, the agility of supply chain operations has become paramount. In addressing the need for speed, flexibility, and efficiency, low-code development platforms have emerged as a revolutionary force in shaping agile supply chain solutions. These platforms offer a transformative approach to creating complex business applications without the prolonged development timelines and deep technical skills traditionally associated with software development.

At the core of low-code platforms lies a user-friendly, visual interface that allows both experienced developers and business analysts to construct and modify workflow applications quickly. Users can piece together application components, much like building blocks, to craft end-to-end solutions tailored to specific supply chain needs. Drag-and-drop functionalities, pre-built templates, and modular frameworks make it straightforward to build applications that manage inventory, streamline procurement processes, optimize logistics, and enhance customer engagement.

One of the most critical advantages of low-code development in supply chains is its capacity to adapt promptly to market changes. As consumer demand, transportation costs, and supplier availability fluctuate, low-code applications can be rapidly adjusted or extended with new functionalities, ensuring that the supply chain remains as responsive as possible. This means businesses can implement changes swiftly, without the need for complex coding or extended downtimes, thus avoiding potential disruptions and maintaining continuity.

Moreover, low-code platforms tend to integrate seamlessly with existing IT ecosystems, including enterprise resource planning (ERP) systems, customer relationship management (CRM) software, and various third-party data sources. Through APIs and pre-configured connectors, low-code solutions can pull in data from across these systems, providing a comprehensive, real-time view of supply chain operations. Enhanced data visibility equips decision-makers to make smarter, data-informed choices, deliver actionable insights, and devise more strategic supply chain management.

Low-code platforms also pave the way for greater collaboration in the context of ever-increasing data volumes and complex supply chain networks. By breaking down silos and aligning cross-functional teams on a singular platform, they foster a more unified approach to supply chain management. Procurement, logistics, sales, and customer service stakeholders can co-create solutions, iterating and refining processes collectively, resulting in harmonized and efficient workflow execution.

AppMaster, as a proponent of the no-code movement, takes this notion a step further by generating production-ready applications out of business process blueprints. Whether it's for optimizing inventory levels using predictive analytics or streamlining logistics planning, AppMaster's platform has extended the capabilities of traditional low-code repositories, consolidating the development lifecycle and empowering users to deploy functionally rich, AI-enabled applications with unprecedented speed.

Low-code platforms have established themselves as pioneers in developing agile supply chain solutions. They enable rapid response to changing market conditions, encourage collaborative innovation, and harness the power of real-time data to elevate supply chain efficiency. As these platforms continue to evolve and integrate cutting-edge technologies like AI and machine learning, the potential for even more profound transformations in supply chain management is on the horizon, ensuring that businesses can confidently meet today's and tomorrow's challenges.

Use Cases of Low-Code AI in Supply Chain Optimization

The fusion of low-code platforms and artificial intelligence (AI) is unlocking many supply chain optimization opportunities. These technologies work in tandem to address complex challenges faced by supply chain managers, offering effective solutions, quick to deploy, and easy to adapt. Below, we delve into several use cases where low-code AI significantly impacts the efficiency and resilience of supply chain operations.

Predictive Analytics for Inventory Management

One of the most beneficial applications of low-code AI in the supply chain arena is in inventory management. With predictive analytics, companies can anticipate demand fluctuations and seasonality, adjusting inventory levels accordingly to prevent stockouts or overstock situations. By using a low-code platform that integrates AI algorithms, businesses can automate the analysis of historical sales data and external factors, such as market trends and weather patterns, to proactively manage their inventory in real-time.

Enhanced Demand Forecasting

Demand forecasting is another domain where low-code AI can play a transformative role. Accurate predictions help in planning production schedules, labor, and logistics. Low-code platforms enable users to build AI models that analyze vast datasets, drawing upon sales history, promotions, and socio-economic indicators to project future demand. The agility of low-code development means these predictive models can be continually refined to improve accuracy over time.

Automated Supplier Selection and Evaluation

Supplier evaluation is a critical function in supply chain management. Low-code AI platforms allow for the development of applications that can automate the supplier selection process, using machine learning to rate and rank suppliers based on performance metrics, delivery times, quality standards, and compliance. This automation significantly speeds up the sourcing process, ensuring businesses work with the best possible partners.

Dynamic Route Optimization for Logistics

Transportation and delivery are substantial cost centers in the supply chain. Low-code AI can be leveraged to optimize delivery routes by processing real-time traffic data, weather conditions, and delivery windows. This results in reduced fuel consumption, faster delivery times, and improved customer satisfaction. Quick adjustments to logistics plans can be made, as low-code applications afford the flexibility to update algorithms without extensive coding.

Intelligent Chatbots for Customer Service

In supply chain management, communication with customers is paramount. Intelligent chatbots created using low-code platforms can assist in handling customer queries regarding order status, delivery times, and returns. These AI-powered chatbots provide quick, consistent responses, which can improve the customer experience while offloading these routine tasks from customer service representatives.

Manufacturing Process Automation

Manufacturing processes can be made more efficient through low-code AI. AI can analyze production line data to predict and identify bottlenecks, allowing for preemptive maintenance or process adjustments. Low-code development platforms enable rapid iteration and deployment of such AI models, ensuring that manufacturing facilities are always operating at peak efficiency.

Real-Time Supply Chain Visibility

Complete visibility into the supply chain is crucial for timely decision-making. Low-code AI platforms can bring together data from various sources – such as GPS, RFID, and IoT devices – to provide a real-time view of the inventory, both in transit and in warehouses. This level of oversight is essential for managing risks and responding swiftly to disruptions.

These are just a few examples of how low-code AI transforms the supply chain. With these advanced capabilities becoming more accessible, businesses can stay agile and competitive in a rapidly changing market. As a participant in this revolution, AppMaster, with its no-code platform, facilitates the creation of innovative applications that harness the power of AI for various aspects of supply chain management, allowing even those without a technical background to take advantage of these advanced technologies.

Challenges and Considerations in Implementing Low-Code AI

While the fusion of low-code platforms and artificial intelligence (AI) promises to revolutionize supply chain management, it has hurdles. To effectively leverage this innovative combination, businesses must recognize and navigate through several challenges and considerations. Here, we'll delve into the common obstacles enterprises may encounter and the strategic considerations they should make when embarking on a low-code AI venture to enhance their supply chain processes.

One primary challenge is data handling and integrity. AI algorithms require massive volumes of high-quality data to deliver accurate predictions and valuable insights. Companies must ensure that data collected from various points in the supply chain is clean, consistent, and comprehensive. Integrating different systems, often through APIs, can sometimes lead to discrepancies and thus compromise the effectiveness of AI algorithms.

Another aspect to consider is the change management required when implementing new technologies. Employees and stakeholders may resist change, especially when it involves trusting AI-driven decisions over human expertise. As such, businesses must invest in training and develop a culture that embraces technological advancements and understands the value that low-code AI can bring to the organization.

Scalability is a further consideration. While low-code platforms enable rapid development and deployment of applications, the infrastructure needs to sustain this growth. Enterprises must ensure that their low-code AI system can handle increased data loads and user demands without performance degradation. Furthermore, they should evaluate whether the AI components can self-improve over time through machine learning, adapting to new patterns in data.

Legally and ethically, companies must be aware of the regulations that govern AI and data usage, particularly in relation to privacy and security. Ensuring compliance with these regulations is paramount, as non-compliance can lead to significant penalties and loss of customer trust.

Finally, businesses must align their low-code AI initiatives with strategic objectives. It's not sufficient to implement AI for its own sake; it should resolve specific challenges or exploit particular opportunities within the supply chain. This requires careful planning, clear goal-setting, and an understanding of how AI can be leveraged to meet those goals.

Businesses considering low-code AI for their supply chain must address the quality of their data, anticipate and manage cultural shifts, ensure scalability and compliance, and align technological initiatives with their strategic vision. Despite these challenges, the rewards of improved efficiency, reduced costs, and enhanced decision-making can make the journey worthwhile.

Future Trends: AI, Low-Code, and the Evolution of Supply Chains

As businesses strive to keep pace with the rapid technological changes, the supply chain sector stands on the cusp of a transformation driven by two significant tech trends: artificial intelligence (AI) and low-code development platforms. These innovative tools are not just redefining how supply chains operate today, but they are also carving out a terrain rife with opportunities for future advancements. Embracing these technologies is set to redefine efficiency, agility, and data-driven decision-making in supply chains across the globe.

Integrated AI and Low-Code Platform

One of the most exciting trends is the deeper integration of AI within low-code platforms, allowing supply chains to leverage complex AI algorithms without needing expert-level data scientists. These AI capabilities range from smart analytics that forecast demand to cognitive services that can enhance customer service through chatbots and automated assistants.

In addition, the fusion of AI with Internet of Things (IoT) devices promises an even more connected and intelligent supply chain. Imagine sensors in a warehouse communicating with an AI over a low-code platform to not only monitor inventory in real-time but predict stock levels, reduce spoilage, and streamline order fulfillment.

Adaptive Supply Chains

Supply chains will become more adaptive and responsive to market changes. As AI models fed by live data learn and improve, supply chains will self-optimize in response to changing patterns in demand, supplies, and logistical challenges. The low-code aspect will enable rapid deployment of these adaptive systems, making them accessible to a broader range of businesses.

Personalized Customer Experiences

AI will customize customer experiences by tailoring logistics and services to individual preferences and behaviors. From personalized delivery options to customized product suggestions based on purchase history, the supply chain will be a direct touchpoint for enhancing customer relationships.

Blockchain for Enhanced Security and Transparency

Further integration of blockchain technology with low-code AI platforms can significantly augment supply chain transparency and security. As blockchain's decentralized ledgers become more accessible through low-code solutions, companies can more readily track products from origin to consumer, guaranteeing authenticity and compliance with regulatory standards.

Emergence of Autonomous Logistics

Logistics automation will advance to higher autonomy levels with AI-powered drones and self-driving vehicles handling deliveries. These cutting-edge technologies, managed through low-code platforms, will potentially remove human error from the equation, enhancing the speed and reliability of logistics operations.

The AppMaster Advantage in Supply Chain Innovation

Amidst these future trends, the AppMaster platform offers a window into this advancing world of supply chain management. Through its no-code capabilities, AppMaster enables businesses to integrate sophisticated backends, interactive web, and mobile apps with AI functionality. This opens doors for companies, even those with limited technical resources, to build highly scalable and flexible supply chain solutions that can adapt to future demands with iterative enhancements.

As AI becomes more sophisticated and low-code platforms like AppMaster evolve, businesses adopting these technologies will likely lead the charge in the revolutionized supply chain sector. The combination of AI's predictive power and low-code's nimbleness will propel operations to new heights and inspire a more dynamic and forward-thinking approach to global supply chain management.

The AppMaster Advantage in Supply Chain Innovation

When exploring the integration of low-code AI within the supply chain, the benefits brought by a platform like AppMaster become extremely valuable. This no-code development platform is at the forefront of transforming how applications are built and how businesses operate in complex environments such as supply chain management.

Using AppMaster, supply chain businesses can harness the power of AI without needing a team of specialized developers. This opens doors for companies of all sizes to innovate and compete in areas traditionally dominated by those with hefty IT budgets. With its visual business process designer, users can easily create and manage business logic, automate workflows, and integrate AI functionalities directly into their applications.

One significant advantage of AppMaster in supply chain innovation is the platform's speed and flexibility. Changes to the supply chain process can be applied and reflected in the system almost instantaneously. Thanks to the automated generation of swagger documentation and database schema migration scripts, ensuring continuity and compliance is easier.

Moreover, with the generation of real, executable applications that can be deployed directly to the cloud or on-premises, supply chain entities can maintain control and security over their digital infrastructure. Whether it's a system for inventory management, logistics coordination, or customer service, AppMaster can deliver a tailored solution that meets the specific needs of a business, which is crucial in the dynamic supply chain sector.

Considering the platform's support for any Postgresql-compatible database paired with the scalability provided by stateless backend applications created in Go, supply chains can ensure that their operations can grow and adapt without the typical constraints associated with custom software development. Seamless integration with existing systems and databases is equally important in preserving investments already made in supply chain technology.

A particularly noteworthy feature is the ability to create and manage mobile applications through the AppMaster platform. In the context of supply chain, where mobility and on-the-go decision making are critical, the capability to craft native mobile apps for iOS and Android provides teams with the tools they need wherever they are. This could be directly on the warehouse floor, in transit, or during last-mile delivery—ensuring seamless integration and real-time insights throughout the entire supply chain process.

Lastly, the community of over 60,000 users, numerous subscriptions tailored to various business needs, and standout recognition by G2 as a High Performer across several categories, affirm the reputation of AppMaster as a leader in no-code development for businesses, including those operating within the dynamic realm of supply chain management.

FAQ

Low-code AI refers to the integration of artificial intelligence capabilities into low-code development platforms. This enables users to design, deploy, and manage AI-enhanced applications with minimal coding, making AI more accessible for supply chain optimizations.

AI can improve supply chain management by offering predictive analytics, demand forecasting, automated inventory management, and facilitating real-time decision-making, thus enhancing operational efficiency and reducing costs.

Low-code platforms shorten development times, reduce the need for extensive programming expertise, enable rapid prototyping, and foster collaborative innovation within supply chain management.

Yes, low-code platforms can be designed to integrate with existing supply chain systems through APIs and pre-built connectors, allowing seamless data flow and functionality between systems.

Use cases include real-time inventory tracking, demand prediction, route optimization for logistics, supplier selection automation, and customer service chatbots.

Challenges include ensuring data quality, managing change within the organization, scalability of created solutions, and aligning the technology with business goals.

Absolutely, low-code AI is particularly beneficial for SMEs as it provides access to advanced AI functionalities without the need for a large team of developers or significant upfront investment.

The future of supply chain management with low-code AI includes increased operational flexibility, data-driven strategies, adaptive logistics networks, and continuous improvement through machine learning.

AppMaster offers a powerful no-code platform capable of incorporating AI into the development of backend, web, and mobile applications, streamlining various aspects of supply chain management.

Yes, by optimizing routes, inventory, and operations, low-code AI can help in making supply chain operations more sustainable by minimizing waste and reducing carbon footprint.

Industries with complex logistics, such as manufacturing, retail, healthcare, and e-commerce, can gain significant advantages from low-code AI in their supply chain operations.

Low-code AI supports decision-making by offering insights derived from data analysis, predicting trends, and enabling scenario planning, thus facilitating more informed and quicker decisions.