Top 10 Features Every Inventory Management System Should Have

Discover essential features that every inventory management system should possess to enhance accuracy, efficiency, and integration in business operations.

Introduction to Inventory Management Systems

Inventory management systems serve as the backbone of effective logistics operations in businesses across industries. These systems are pivotal to maintaining a seamless flow of goods from suppliers to customers. By leveraging technology, companies can ensure that they have the right products available at the right time while minimizing overhead costs associated with excess inventory.

What is an Inventory Management System?

An inventory management system is a software solution designed to efficiently manage and control the stock of goods a business holds. It encompasses various processes such as ordering, storing, and using a company's inventory. The system aims to optimize inventory levels, enhance order fulfillment rates, and increase overall operational efficiency.

The advent of these systems has revolutionized how businesses handle their inventories, moving away from manual count methods and allowing for digital tracking of stock levels, orders, sales, and deliveries. With a robust inventory management system, businesses can minimize human error, reduce labor costs, and improve accuracy.

The Evolution of Inventory Management

Traditionally, inventory management was a purely manual task carried out using paper-based logs and spreadsheets. This method posed significant challenges in maintaining up-to-date inventory records, often leading to discrepancies that could disrupt business operations.

The introduction of computerized inventory systems marked a significant advancement, enabling businesses to digitize their stock control processes. Over time, these systems have evolved to incorporate more sophisticated features, such as real-time tracking, analytics, and integration with other business processes, thereby bolstering effectiveness and efficiency in inventory management.

The Role of Technology

Technology is at the core of modern inventory management systems. Innovations such as barcode scanning, RFID (Radio Frequency Identification) technology, and cloud-based services are fundamental components of these systems. They enable businesses to track inventory with remarkable accuracy, automate inventory counts, and gain valuable insights from data analytics.

In summary, inventory management systems are indispensable to any business involved in the production, distribution, or sale of goods. With the capability to boost accuracy, enhance operational flexibility, and ultimately improve customer satisfaction, these systems are an investment that offers substantial returns for businesses.

Importance of Effective Inventory Management

Effective inventory management is the backbone of any successful business, regardless of its size or industry. It plays a critical role in ensuring that a business can meet customer demand, maintain optimal stock levels, and operate efficiently. This section delves into why effective inventory management is crucial for modern businesses.

Enhancing Customer Satisfaction

At the heart of business success lies customer satisfaction, which is significantly influenced by how well a company manages its inventory. When a business efficiently tracks and manages its stock, it minimizes the risk of encountering stockouts, backorders, or delays that could disappoint customers. Satisfied customers are more likely to be repeat buyers, bolstering long-term revenue and brand loyalty. An effective inventory management system ensures that stocks are readily available to meet orders promptly, thus enhancing customer satisfaction levels.

Optimizing Operational Efficiency

Efficient inventory management streamlines various operational aspects, saving both time and resources. By automating manual processes like stock counting and order processing, businesses can allocate their resources more effectively, focusing on core operations and strategic growth. Effective systems also provide accurate data on stock levels, helping to reduce carrying costs associated with overstocking or wasting storage space.

Supporting Financial Health

Inventory constitutes a significant portion of a business’s assets. Mismanaged stock can lead to unnecessary capital tied up in unsold goods or wasted due to obsolescence, directly impacting cash flow. Effective inventory management helps maintain optimal inventory levels, ensuring that capital is not unnecessarily kept in overstocked items, thus improving liquidity and financial health.

Facilitating Informed Decision-Making

An effective inventory management system furnishes businesses with real-time data and analytics about their stock movements, purchasing patterns, and sales. This data empowers business owners and managers with insights that inform strategic decision-making. For example, analytics can reveal which products are fast-moving, aiding in accurate forecasting and resource allocation.

Supporting Scalability and Growth

As businesses grow, managing inventory becomes more complex, especially when expanding into new locations or diversifying product lines. An effective inventory management system is scalable and accommodates the changing needs of a growing business, allowing seamless transitions into new markets or expansion. It ensures that the business can handle increased demand without compromising on service quality or operational efficiency.

In conclusion, effective inventory management is indispensable to any business aspiring for efficiency, profitability, and sustainable growth. Investing in a comprehensive inventory management system can provide businesses with powerful tools to manage their inventory effectively, reduce costs, and enhance customer satisfaction — all crucial components for thriving in today’s competitive market.

Real-Time Inventory Tracking

In the world of inventory management, real-time inventory tracking stands out as an indispensable feature that ensures greater accuracy and operational efficiency. With the digital transformation reshaping business landscapes, having instant insights into stock levels is crucial for maintaining seamless operations and fulfilling customer expectations.

Benefits of Real-Time Inventory Tracking

Real-time tracking offers several key benefits that contribute to the overall health of a business's supply chain and inventory management practices:

- Accurate Stock Levels: With up-to-the-minute data, businesses can confidently assess their available inventory at any given time, minimizing the risk of errors due to manual entry or delayed updates.

- Prevention of Stockouts: Real-time tracking allows businesses to respond swiftly to low inventory alerts, ensuring that they replenish products before they run out, thereby preventing stockouts and potential sales losses.

- Reduction of Excess Inventory: By continuously monitoring inventory levels, companies can better forecast demand and avoid overstocking, which ties up capital and increases storage costs.

- Improved Order Fulfillment: With accurate data on hand, businesses can process orders more efficiently and fulfill them quickly, enhancing customer satisfaction through timely deliveries.

Technology Behind Real-Time Tracking

The implementation of real-time tracking within inventory management systems often relies on advanced technologies, including:

- Barcodes and RFID: These technologies automate the tracking process, allowing for quick capturing of product information as they move through the supply chain.

- Internet of Things (IoT): IoT devices can connect inventory assets to a central system, facilitating the constant monitoring of stock levels and conditions. This connectivity aids in eliminating manual checks.

- Cloud Computing: Cloud-based platforms provide ubiquitous access to inventory data, ensuring that stakeholders can access real-time information from anywhere, anytime.

Real-time inventory tracking is not just a feature; it's a strategic advantage in today's market, offering reliability, competitive edges, and operational efficiency.

Automated Reordering Capabilities

In the dynamic world of inventory management, maintaining the delicate balance between supply and demand is crucial. This is where automated reordering capabilities become an invaluable feature of modern inventory management systems. By optimizing the procurement process, businesses can avert the pitfalls of stockouts and excess inventory, achieving higher efficiency and cost savings.

Ensuring Just-in-Time Inventory

Automated reordering is designed to facilitate the just-in-time (JIT) inventory management strategy. This system automatically generates purchase orders when stock levels dip below a prescribed threshold. By leveraging historical sales data and predictive analytics, the system ensures that inventory is replenished only when necessary, effectively minimizing the costs associated with holding excess stock.

Reducing Manual Intervention

One of the standout advantages of automated reordering is its ability to minimize human error. Manual tracking and ordering can often lead to delays and inaccuracies, affecting production schedules and customer satisfaction. By automating the process, the chances of errors are significantly reduced, and the procurement team can focus on strategic tasks instead of tedious data entry and monitoring tasks.

Integrating with Supplier Systems

Today’s automated reordering features are often integrated gracefully with supplier management systems. Such synchronization ensures that suppliers are consistently apprised of the stock needs, allowing them to prepare and respond swiftly. This level of connectivity fosters stronger relationships between businesses and their suppliers, leading to more advantageous negotiation terms and improved lead times.

Optimizing Inventory Levels

Effective inventory management isn’t solely about avoiding stockouts; it’s also about optimizing inventory to release tied-up capital. Automated reordering solutions excel in offering businesses an objective lens into their order quantities, adjusting based on current trends and seasonal variations. The result is a reduction in unnecessary stock, providing companies with nimble cash flow and warehousing cost savings.

Benefits of Real-Time Data Insights

Automated reordering features are augmented by real-time data insights that feed into the ordering process, making it far more responsive and accurate. Such systems pull data from various touchpoints within the business, ensuring that every reordering decision is grounded in comprehensive, up-to-date information. This technology not only reacts to inventory needs but also anticipates them, allowing businesses to be always one step ahead.

Ultimately, automated reordering capabilities transform inventory management from a reactive to a proactive process. By ensuring timely and optimal stock levels, businesses can focus on their core competencies, secure in the knowledge that their inventory needs are thoroughly managed and aligned with their strategic goals.

Comprehensive Reporting and Analytics

In today's competitive business environment, having a comprehensive reporting and analytics feature in an inventory management system is not just a luxury — it's a necessity. An efficient system equips businesses with the tools they need to understand the intricate dynamics of their inventory and operations, offering strategic insights for decision-making.

Driving Data-Driven Decisions

Comprehensive reporting and analytics tools allow businesses to harness vast amounts of data to drive informed strategies. By accessing detailed reports, companies can unlock hidden patterns and correlations within their inventory flow, which is pivotal for improving efficiency and reducing unnecessary costs. The capability to delve into granular data provides clarity on which products are performing well and which are lagging, enabling timely interventions.

Analyzing Stock Movement and Turnover Rates

Understanding stock movement is a critical aspect of inventory management. Analytics allows businesses to gauge inventory turnover rates — how quickly inventory is being sold and replaced over a specific period. A high turnover rate indicates a healthy inventory system, minimizing the holding costs associated with storage, while a low turnover rate might necessitate re-evaluation of stock levels and sales strategies. With these insights, businesses can adjust their procurement and sales tactics proactively, ensuring optimal inventory levels.

Forecasting and Demand Planning

Inventory analytics play a vital role in forecasting and demand planning. By analyzing historical sales data and identifying market trends, businesses can predict future demand with greater accuracy. This ensures that inventory levels are aligned with anticipated demand, reducing the risk of stockouts or overstock situations. Accurate demand forecasting translates to better customer satisfaction, streamlined operations, and increased profitability.

Identifying Seasonal Trends and Patterns

Seasonal trends can significantly impact inventory levels, and businesses that can anticipate these shifts are better positioned to capitalize on market opportunities. Reporting tools in inventory management systems allow businesses to recognize recurring patterns and adapt their strategy accordingly. Whether it's stocking up on holiday-themed products or preparing for post-season sales lulls, understanding these trends enables businesses to allocate resources effectively.

Enhancing Vendor Management

Vendor management is another domain where reporting and analytics shine. Businesses can assess supplier performance by analyzing order lead times, delivery accuracy, and quality consistency. With this information at hand, companies can formulate strategic supplier relationships, negotiate better terms, and ensure consistent supply chain operations. This level of insight is invaluable for maintaining a robust inventory ecosystem that supports business growth.

Real-Time Insights and Dashboards

Real-time dashboards provide businesses with an on-demand snapshot of their inventory status. Dynamic visuals and interactive graphs offer an at-a-glance understanding of stock levels, trends, and key performance indicators (KPIs). This instant access empowers decision-makers to respond quickly to inventory challenges, streamline operations, and pivot strategies as needed.

The effectiveness of a reporting and analytics feature in an inventory management system lies in its ability to aggregate data from diverse sources into coherent, actionable insights. With the right tools in place, businesses can transform raw data into robust strategies that drive performance and growth.

Multi-Location Management

In today's globalized market, businesses often operate across multiple locations, ranging from regional distribution centers to international warehouses. Managing inventory across these various locations is crucial for maintaining smooth operations and meeting customer demands efficiently. Multi-location management within an inventory management system ensures that businesses can oversee their inventory levels across different sites without confusion or overlap in data.

Here are some of the key reasons why multi-location management is an essential feature for inventory management systems:

1. Centralized Inventory Visibility

Multi-location management offers a centralized platform that provides real-time visibility into the inventory levels at each location. This transparency is critical when fulfilling orders since it allows businesses to select the most appropriate location to ship from based on factors such as proximity to the delivery address or inventory availability.

2. Efficient Resource Utilization

Effective multi-location management means businesses can utilize their resources more efficiently. Instead of having excess stock sitting idle in less active locations, companies can redistribute inventory across locations based on demand forecasts and sales trends. This strategy reduces holding costs and enhances cash flow by ensuring that inventory is maintained at optimal levels.

3. Planning and Forecasting

Forecasting inventory needs is a pivotal aspect of inventory management, and it becomes increasingly complicated when multiple locations are involved. A proficient inventory management system with multi-location capabilities can gather data from all locations and provide comprehensive analytics for better demand forecasting. This predictive capability allows businesses to make informed decisions and minimize disruptions to supply chains.

4. Location-Based Inventory Movement

As businesses grow, relocating merchandise between different sites becomes inevitable. Multi-location management supports this by allowing seamless transfers of stock between locations while keeping an accurate record of inventory movement. This feature minimizes the chances of errors and ensures that every unit is accounted for, boosting overall efficiency.

5. Customized Access and Permissions

When handling inventory across multiple locations, it's essential to manage who has access to what information. A multi-location management feature allows businesses to allocate different roles and permissions based on each employee’s responsibilities and location. This level of control is vital for maintaining data security and ensuring that sensitive data is available only to authorized personnel.

6. Stock Level Balancing and Replenishment

The ability to automatically balance stock levels across locations is one of the primary benefits of multi-location inventory management. Businesses can set parameters for each location and automate the procurement and distribution processes to ensure that stock levels remain balanced. This functionality helps prevent stockouts and overstocking across the supply chain.

In conclusion, multi-location management is indispensable for businesses looking to optimize their inventory management practices. It enhances visibility, resource utilization, planning efficiency, and security across all operational locations. By incorporating a feature-rich inventory management system, businesses can efficiently manage their expansive operations while maintaining flexibility and responsiveness in an ever-evolving market.

Integration with Other Business Systems

In the competitive business world, seamless integration between systems has emerged as a critical requirement for efficiency and accuracy. An inventory management system that integrates effortlessly with other business applications can significantly enhance operational workflows. Integrating with systems like ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and accounting software offers multiple advantages and can play a pivotal role in streamlining inventories.

Enhanced Data Flow and Accuracy

Integrating an inventory management system with other business applications facilitates a smooth flow of accurate data across different departments. It eliminates the need for manual data entry, reducing the chances of human error. Automatically synchronizing stock numbers, order details, and shipping information ensures that all stakeholders work with real-time data, avoiding discrepancies that could result in stockouts or over-committed inventories.

Improved Operational Efficiency

Integrated systems boost operational efficiency by connecting different business processes. For example, integration with CRM systems provides sales teams with immediate access to inventory data, enabling them to update customers about availability instantly. Likewise, linking the inventory system with accounting software can automate invoice generation and directly update financial records, saving invaluable time and resources.

Better Supply Chain Management

By linking procurement, warehouse, and distribution channels, businesses can optimize their supply chain processes. Automatic updates from suppliers about inventory level changes help better align purchase orders with stock demands, reducing lead times. Moreover, instant visibility into the supply chain allows decision-makers to respond promptly to fluctuating market conditions or unexpected disruptions, ensuring business continuity.

Informed Decision-Making

Integrations provide a treasure trove of data to help in informed decision-making. By analyzing data from integrated systems, businesses can gain insights on consumer behavior, inventory turnover rates, and SKU performance. These analytical insights empower businesses to improve forecasting, allocate resources cleverly, and make strategic moves toward growth. It is this combination of information gathered from different systems that help businesses maintain a competitive edge.

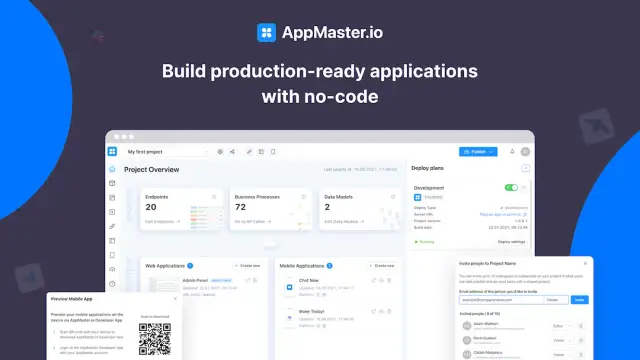

AppMaster’s Role in System Integration

AppMaster, the leading no-code app builder, offers the benefits of seamless integration by allowing businesses to build custom applications suited to their specific operational needs. Its ability to generate backend, web, and mobile applications from scratch means users can create bespoke systems that interconnect without adding technical debt. With AppMaster, you can easily define data models and create business logic to ensure the comprehensive handling of inventory integration tasks.

In conclusion, integrating an inventory management system with other business systems is invaluable for improving data accuracy, operational efficiency, supply chain management, and informed decision-making.

User-Friendly Interface

In the realm of inventory management systems, a user-friendly interface stands as a pivotal element in ensuring that operations run smoothly and efficiently. A user-friendly interface is more than just a well-designed dashboard; it is the gateway through which users interact with the system, and its importance cannot be overstated in fostering a productive work environment.

The Importance of Simplicity and Intuitiveness

The simplicity and intuitiveness of an interface directly impact the user experience. For an inventory management system to be effective, it should require minimal training and adapt to the user’s workflow seamlessly. Users, especially those who might not be tech-savvy, should not feel overwhelmed when navigating through the system.

A straightforward design, clear visual cues, and logical navigation paths help in reducing the learning curve significantly. This, in turn, allows businesses to allocate fewer resources towards extensive training sessions and more towards increasing operational efficiency. Employees can focus more on their core responsibilities rather than spending time deciphering complex software functionalities.

Customizable Dashboards

Another critical aspect is the customization capability of dashboards. A user-friendly interface should allow users to personalize their workspace according to their roles and responsibilities. For instance, an employee in charge of tracking shipments might want quick access to supplier information, while a sales manager might prioritize sales trends and product availability.

By providing options for customization, inventory management systems cater to the specific needs of different departments, facilitating a more relevant and streamlined user experience. This customization fosters an environment where employees can access pertinent information more rapidly, leading to more proactive decision-making.

Minimization of Manual Entry

Reducing manual data entry decreases the likelihood of human error and enhances efficiency. A user-friendly interface should make it easy to automate repetitive tasks and integrate seamlessly with other business systems, such as ERP and CRM platforms.

Automation of processes like data collection from barcode scanners or RFID technology plays a crucial role in minimizing manual input, resulting in greater data accuracy and freeing up time for employees to focus on value-adding activities. Automation also provides real-time data availability, which is vital for making informed decisions.

Responsive Design with Mobile Support

A truly user-friendly interface is also responsive, meaning it can adapt to different devices and screen sizes without compromising on functionality or clarity. As businesses become more mobile-centric, having an inventory management system that is accessible from smartphones and tablets becomes essential.

Mobile support ensures that personnel can access and update inventory data on-the-go, enhancing collaboration and response times, particularly in scenarios where quick decision-making is imperative. Whether they're on the field, at a warehouse, or in a remote location, users should enjoy the same level of access and functionality as they would from a desktop environment.

Feedback Mechanisms and Continuous Improvement

Implementing an effective feedback mechanism is another vital feature of a user-friendly interface. It is important to gather insights from users regularly to identify areas for improvement. Continuous improvement based on user feedback keeps the system aligned with evolving business needs and technological advancements.

By building a feedback loop into the inventory management system, developers can ensure that the interface remains relevant and effective in the long term. This iterative process not only enhances user satisfaction but also ensures that the system evolves in line with industry standards and best practices.

Barcode Scanning and RFID Technology

In contemporary inventory management systems, the incorporation of barcode scanning and RFID (Radio Frequency Identification) technology has dramatically transformed the way businesses handle their stock. These technologies provide significant benefits, enhancing not only the efficiency of inventory processes but also the accuracy of data collection and management.

Advantages of Barcode Scanning

Barcode scanning is a fundamental feature that has revolutionized inventory management by automating the data entry process. Here are some key advantages:

- Speed and Efficiency: Scanning a barcode is much faster than manual entry or counting. This efficiency allows businesses to process inventory transactions swiftly, reducing waiting times and increasing productivity.

- Accuracy: Human errors are minimized when data entry is automated through barcode scanning. This precision helps maintain accurate inventory records, which is crucial for effective decision-making and reporting.

- Cost-Effectiveness: While the initial setup may involve purchasing scanners and integrating them with an inventory system, the long-term savings from reduced errors and increased labor efficiency offset these initial costs.

- Ease of Use: Barcodes are simple to implement and work seamlessly with databases, making it easy for employees to handle them without extensive training.

- Real-Time Updates: Inventory management systems equipped with barcode scanning can update inventory levels in real-time, ensuring that stock levels are always current and facilitating proactive inventory management.

The Role of RFID Technology

RFID technology represents a more advanced step in inventory tracking, offering numerous benefits over traditional barcode scanning:

- Non-Line-of-Sight Reading: Unlike barcodes, RFID tags do not require a direct line of sight to be read. This allows for quicker and more flexible inventory checks.

- Batch Scanning: RFID systems can read multiple tags simultaneously, making them ideal for environments where large quantities of items need to be processed rapidly.

- Improved Accuracy and Control: RFID's automatic and continuous data gathering decreases the chances of human errors, enhancing inventory accuracy and control.

- Durability and Reliability: RFID tags are generally more durable than barcodes, making them suitable for harsh environments where barcodes might become damaged or unreadable.

- Comprehensive Tracking: RFID technology can store more information than a simple barcode, allowing businesses to track additional product details and history.

Implementing Barcode and RFID in Inventory Systems

Adopting these technologies requires a well-thought-out strategy:

- Assessing Needs: Businesses need to evaluate their specific inventory management needs to determine whether barcode scanning, RFID, or a combination of both is the most beneficial.

- Cost-Benefit Analysis: Consider the costs associated with implementing RFID or barcode scanning technology compared to the long-term gains in efficiency and accuracy.

- System Compatibility: Ensure that the chosen technology is compatible with existing systems or consider upgrading to solutions which support integration with various inventory management tools.

- Training and Support: Providing comprehensive training for staff is crucial in maximizing the benefits of the new technology. Ongoing support for troubleshooting and optimization should also be available.

Both barcode scanning and RFID technology exemplify how technological innovations can significantly enhance inventory management systems. By implementing these technologies, businesses not only streamline their operations but also gain comprehensive control over inventory processes, facilitating improved resource management and overall business efficiency.

Cloud-Based Accessibility

In recent years, the advent of cloud technology has revolutionized various facets of business operations, and inventory management is no exception. Cloud-based accessibility has emerged as a pivotal feature for modern inventory management systems, offering an array of benefits that enhance the efficiency and effectiveness of managing inventory.

Seamless Remote Access

One of the foremost advantages of cloud-based inventory management systems is the ability to access data from anywhere, at any time. This level of accessibility is critical for businesses that operate across multiple locations or have a remote workforce. Employees are no longer bound by the constraints of being onsite, enabling decision-makers to make informed choices based on real-time data even when they are not physically present at a specific location.

Enhanced Collaboration and Coordination

Cloud-based systems inherently promote better collaboration among teams. Since information is stored and updated in real time, different departments can work together cohesively without the risk of data silos or discrepancies. This ensures that the sales team has accurate information about stock availability, while the procurement team can seamlessly coordinate orders to replenish inventory cycles.

Furthermore, cloud technology facilitates integrated communication tools and platforms that further amplify collaboration opportunities, making it easier for teams to align their priorities and operational objectives.

Scalability and Flexibility

As businesses grow, their inventory management needs intensify, requiring systems that can scale accordingly. Cloud-based inventory management solutions provide this scalability effortlessly. Businesses can adjust their resources, storage, and processing capabilities based on current requirements without spending extensively on new hardware or infrastructure.

This flexibility is invaluable for businesses experiencing fluctuations in demand or those planning for significant growth. Cloud solutions make it possible to seamlessly increase capacity when needed and scale down during less demanding periods, optimizing cost-efficiency.

Cost-Effectiveness

Implementing a cloud-based inventory management system often results in cost savings. Traditional systems may require significant upfront investments in hardware, software licenses, and maintenance. In contrast, cloud-based platforms operate on subscription models, spreading costs over time and allowing businesses to budget more efficiently.

Moreover, the reduction of manual processes and the elimination of expensive onsite IT infrastructure contribute to overall savings, freeing up resources for other strategic investments.

Data Security and Backup

Data security concerns are legitimate, but cloud providers often invest extensively in state-of-the-art security measures. These measures typically include encryption, multi-factor authentication, and regular security audits to protect against unauthorized access and data breaches. Cloud-based systems also offer reliable backup facilities, ensuring data integrity and the possibility of restoring data in the event of accidental deletion or corruption.

Automatic Updates and Innovations

A significant advantage of cloud-based solutions is the automatic integration of software updates and new features. With zero downtime and without the need for manual intervention, businesses benefit from continuous improvements in system performance and capabilities. This ensures that businesses are always equipped with the latest technologies, allowing them to maintain a competitive edge in their operations.

Employing a cloud-based inventory management system allows companies to stay ahead of technological advancements, reflecting a proactive approach to both business growth and risk management.

In conclusion, cloud-based accessibility within inventory management systems represents a transformative shift that empowers businesses to operate with greater flexibility, coordination, and security.

Customizable Alert System

An effective inventory management system should incorporate a customizable alert system to ensure that businesses can remain proactive rather than reactive. With the dynamic nature of inventory demands, having a system that can notify relevant personnel about critical changes can significantly impact operational efficiency.

Why Customizable Alerts Matter

Customizable alerts offer an efficient means of maintaining control over inventory management. They allow businesses to tailor notifications to their specific needs and thresholds. This ensures timely decision-making, preventing potential disruptions in the supply chain. By setting precise alerts for low stock levels, delivery delays, or excess inventory, businesses can mitigate risks associated with poor inventory control.

Key Benefits of Customizable Alert Systems

- Proactive Management: Customizable alerts help managers stay informed about critical inventory metrics in real time, preventing the issues associated with stockouts or overstocking.

- Reduced Human Error: Automating alerts based on specific criteria reduces reliance on manual checks and minimizes the chances of human error.

- Enhanced Communication: Alerts can notify the appropriate team members or departments, ensuring swift communication and quicker resolution of potential issues.

- Cost Efficiency: By optimizing inventory levels through timely alerts, businesses can reduce holding costs and improve the overall cost efficiency of their operations.

Features of an Effective Customizable Alert System

To achieve the desired level of efficiency, customizable alert systems should possess several key features:

- Configurable Thresholds: Ability to set different thresholds for various items or groups of items based on demand and priority.

- Multi-Channel Notification: Options to receive alerts via email, SMS, mobile app notifications, or direct integration with business communication tools such as Slack.

- Prioritization: Ability to categorize alerts by urgency for better focus on critical issues.

- Historical Data Analysis: Integration with reporting tools to analyze alert efficacy and adjust thresholds as necessary based on historical patterns.

- Scalability: Adaptability to accommodate the growing inventory needs of businesses without requiring a complete overhaul of the alert system.

These features not only improve the operational capacity but also ensure that decision-makers are well-equipped with crucial data to maintain smooth workflows.

In conclusion, incorporating a customizable alert system into your inventory management strategy is vital for maintaining efficiency and ensuring that your operations remain uninterrupted.

FAQ

An inventory management system is software designed to track, manage, and control inventory levels, orders, and deliveries for businesses.

Real-time inventory tracking ensures that businesses have up-to-date information about stock levels, reducing the risk of stockouts or overstocking.

Automated reordering streamlines the procurement process by triggering purchase orders when stock levels fall below a pre-set threshold, ensuring goods are ordered just in time.

Analytics provides insights into purchasing patterns, sales trends, and inventory turnover, helping businesses make data-driven decisions.

Multi-location management allows businesses to oversee inventory levels at different sites, facilitating efficient distribution and reducing logistics costs.

Integration ensures seamless data flow between departments, enhancing coordination and reducing the chances of errors across platforms like ERP and accounting systems.

Barcode and RFID technology streamline the tracking process, allowing for faster and more accurate inventory updates.

Cloud-based systems provide remote access to inventory data, facilitating real-time collaboration and decision-making without geographical constraints.

Customizable alerts notify the relevant staff about critical inventory changes, such as low stock levels or delivery delays, enabling proactive management.

A user-friendly interface should be intuitive, easy to navigate, and reduce manual entry processes, minimizing user training time.