The Role of ERP in the Manufacturing Industry

Explore the role of ERP systems in the manufacturing industry, the benefits of implementing these systems, and how to choose the right solution for your organization.

The Importance of ERP Systems in Manufacturing

In the manufacturing industry, managing resources, processes, and data efficiently is pivotal to ensuring smooth operations and maintaining a competitive edge. Enterprise Resource Planning (ERP) systems have become an essential tool for manufacturers, as they integrate various functions of the business into a single, unified platform. These systems facilitate efficient management of crucial manufacturing aspects, such as production planning, inventory control, quality management, and supply chain coordination.

The primary objective of an ERP system is to provide a comprehensive view of the entire business operations and enable data-driven decision-making. By offering real-time access to accurate information and fostering effective communication among departments, ERP systems help manufacturers work collaboratively and accelerate the decision-making process.

When properly implemented, ERP systems can offer numerous benefits, including improved operational efficiency, better demand forecasting, and reduced manufacturing lead times. Moreover, modern ERP solutions can be highly customizable to cater to the specific needs of different manufacturing subsectors, making them an indispensable tool for manufacturers striving for excellence in a competitive global market.

Benefits of ERP Implementation for Manufacturers

Manufacturers in various industries can experience significant improvements in their operations and overall performance by implementing ERP systems. Here are some of the key benefits:

- Enhanced Productivity: ERP systems streamline workflows by automating repetitive tasks and providing real-time visibility into operations. They enable employees to focus on value-added activities, thus increasing overall productivity.

- Reduced Operational Costs: By facilitating better utilization of resources and shedding light on areas where costs can be trimmed, ERP systems help manufacturers curb their operational expenses.

- Improved Data Accuracy: Manual data entry processes can lead to errors that can have adverse effects on the business. ERP systems minimize these errors by automating data entry and validation, ensuring that decision-makers have access to reliable information.

- Better Inventory Management: With features like real-time inventory tracking and demand forecasting, ERP systems help manufacturers optimize their inventory levels, minimize stockouts, and reduce excess or obsolete stock.

- Enhanced Customer Satisfaction: ERP systems enable manufacturers to improve customer service through better order tracking, timely communication, and faster order processing and fulfillment.

- Scalability and Flexibility: Modern ERP solutions are highly configurable and adaptable, allowing them to cater to the dynamic needs of a growing manufacturing organization.

Key Features of ERP Systems for Manufacturing

While ERP systems come with a broad array of features, some are particularly relevant to the manufacturing sector. Understanding these key functionalities can help you identify the right ERP solution for your manufacturing business.

- Production Planning and Scheduling: An ERP system should offer planning and scheduling capabilities, enabling manufacturers to optimize production schedules, allocate resources efficiently, and minimize downtime and bottlenecks in the production process.

- Inventory Management: Efficient inventory management is crucial for manufacturers. ERP systems should provide real-time inventory tracking, demand forecasting, and tools for optimizing stock levels to prevent stockouts and reduce carrying costs.

- Quality Control: Maintaining high product quality is crucial in any manufacturing operation. ERP systems should include quality management tools that facilitate tracking, analysis, and improvement of product quality throughout the production process.

- Supply Chain Management: ERP systems should offer comprehensive supply chain management features, such as supplier evaluation, purchase order management, and logistic planning, enabling manufacturers to improve their supplier relationships and optimize their procurement processes.

- Sales and Purchase Order Management: ERP systems should support the complete sales and purchase order management lifecycle, including order creation, tracking, invoicing, and shipping, ensuring timely delivery to customers and efficient management of purchase orders from suppliers.

- Finance Management: An integral part of an ERP system, finance management features ensure that all financial transactions and records are accurately captured and recorded, enabling manufacturers to have a clear overview of their financial health and make informed decisions based on accurate data.

Identifying the right ERP system for your manufacturing business not only requires an understanding of these key features but also a thorough evaluation of the specific customization, scalability, and integration capabilities that your organization may require.

Choosing the Right Manufacturing ERP Solution

Although Enterprise Resource Planning (ERP) systems provide numerous advantages for businesses, selecting the one that’s best for your manufacturing organization is vital to maximize its benefits. Here’s a guide to help you choose the right manufacturing ERP solution:

Industry-specific features

Ensure the ERP system caters to your manufacturing industry’s specific requirements, such as process, discrete, or mixed-mode production environments. Examples of industry-specific features include product lifecycle management, recipe formulation for process manufacturers, and support for made-to-order or made-to-stock production methods.

Scalability

As your business grows, the ERP system should be able to accommodate increasing users, transactions, locations, and other resources. To support your organization’s growth, a scalable ERP system is a crucial factor to consider.

Cloud vs. on-premise deployment

Deciding between a cloud-based ERP system or an on-premise solution depends on your organization's needs and preferences. Cloud-based systems offer lower upfront costs, easy upgrades, and remote accessibility. On the other hand, on-premise solutions provide better control over data security and customization possibilities, although they might require substantial initial costs and in-house maintenance.

Integration capabilities

An ERP system should be capable of seamless integration with your existing software systems, such as CRM, MES, PLM, and e-commerce platforms. Good integration capabilities will maximize the system's effectiveness and minimize disruptions during the implementation process.

Vendor support and services

Evaluate the expertise, track record, and support services of the ERP solution providers. Effective vendor support through implementation, customization, and after-sales services greatly contributes to the success of the ERP system. It's essential to also consider the vendor's long-term strategic vision and commitment to continuous product enhancements.

Cost-effectiveness and ROI

While evaluating ERP systems, assess the return on investment (ROI) based on factors such as efficiency improvements, cost savings, and revenue increment. Choose a cost-effective ERP system that generates a positive ROI in the long run and justify the required investments.

By considering these factors, you can choose an ERP solution that best suits your manufacturing organization's needs, ensuring a smoother implementation process and improved efficiency across the board.

Integration with No-code Platforms for Customization

No-code platforms, like AppMaster, enable rapid configuration and customization of software solutions without the need for extensive programming knowledge. Integrating your ERP system with a no-code platform can provide several advantages:

- Easier customizations: No-code platforms can help you modify and adapt your ERP system to fit your organization's specific requirements, ensuring the solution perfectly fits your business processes.

- Faster implementation: By reducing the time and resources spent on custom development, the overall implementation timeline can be significantly shortened, allowing you to benefit from the ERP system more quickly.

- Greater agility: As your organization evolves, a flexible no-code platform will help you make changes to the ERP system and support new business requirements without the need for extensive coding or development resources.

- Empowered citizen developers: By allowing non-technical team members to contribute to system customizations, no-code platforms empower a broader range of personnel to contribute to the successful implementation and evolution of the ERP solution.

Using a no-code platform like AppMaster can significantly streamline the process of configuring, implementing, and adapting your manufacturing ERP system, ensuring that it remains an effective and relevant tool as your business evolves.

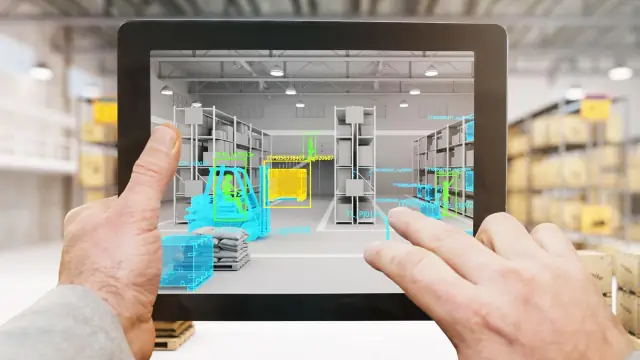

Preparing for Industry 4.0 with ERP

The fourth industrial revolution, also known as Industry 4.0, is driven by the digitization and automation of manufacturing processes. Implementing ERP systems in manufacturing companies can help them prepare for the challenges brought about by Industry 4.0 in several ways:

- Data-driven decision-making: ERP systems provide manufacturers with real-time data that helps them make informed decisions, identify inefficiencies, and optimize production processes. By leveraging insights from data analytics, manufacturers can better adapt to Industry 4.0.

- Connectivity and communication: As a centralized data hub, ERP systems facilitate communication within and across departments, fostering efficient collaboration and faster response times. With Industry 4.0 connecting production, logistics, and other business aspects, streamlined communication and data sharing become increasingly critical to driving operational improvements.

- Support for automation initiatives: ERP systems are essential for successful smart factory operations, where data must be exchanged readily among various elements, including IoT devices, sensors, and production equipment. ERP systems help capture, process, and manage data from automated processes and drive further automation capabilities.

- Digital transformation: The integration of ERP systems is a crucial step in digital transformation, as these platforms enable manufacturers to streamline operations, improve efficiency, and enhance data visibility across the organization. By successfully implementing an ERP system, manufacturers lay the groundwork for fully embracing Industry 4.0.

By implementing ERP systems in manufacturing organizations, businesses can reap the benefits of increased efficiency, data-driven decision-making, and better preparedness for the challenges and opportunities presented by Industry 4.0.

FAQ

ERP systems play a crucial role in the manufacturing industry by streamlining operations, improving efficiency, enabling real-time data access, and facilitating collaboration across departments.

Manufacturers benefit from ERP implementation through increased productivity, reduced operational costs, improved data accuracy, better inventory management, and enhanced customer satisfaction.

Key features include production planning, inventory management, quality control, supply chain management, sales and purchase order management, and finance management.

Selecting the right ERP solution requires considering factors like industry-specific features, scalability, cloud vs. on-premise deployment, integration capabilities, and the vendor's support and services.

Yes, ERP systems can be integrated with no-code platforms like AppMaster, allowing for customization and flexibility without the need for extensive coding knowledge.

ERP systems help manufacturers prepare for Industry 4.0 by enabling data-driven decision-making, improving connectivity and communication, and supporting automation and digital transformation initiatives.