Wholesale reorder portal: one-click reorders with saved pricing

Build a wholesale reorder portal with saved price lists and a one-click reorder last order flow to speed up repeat purchases and reduce errors.

Why wholesale reorders are slower than they should be

Repeat buyers usually know what they need. The slow part is everything around the order.

Many wholesale teams still run reorders through email threads, PDFs, and spreadsheets. That forces buyers (or your reps) to retype the same SKUs and quantities again and again. Manual entry creates predictable mistakes: someone grabs a similar SKU, copies an old order that includes a discontinued item, or uses the wrong price list.

Important details also slip when an “order” is basically a message. Shipping terms, minimums, pack sizes, taxes, and payment terms are easy to miss. When something is unclear, the buyer stops, emails a question, and waits. A quick reorder turns into a half-day task.

Buyers expect three things from B2B ordering: speed, accuracy, and clarity. They want to see their price, their products, and a clear total before they commit. They also want a normal, built-in way to repeat what worked last time, ideally through a wholesale reorder portal where “reorder last order” is a standard action.

Sellers want the same outcome for different reasons. When reorders are slow and messy, you end up with more back-and-forth to confirm items and pricing, more credits and returns from wrong SKUs or stale prices, more support tickets about invoices and terms, and slower cash because orders sit in review.

A well-designed one-click reorder flow doesn’t just save time. It reduces mistakes by keeping products, pricing, and terms tied to the customer account, so the fastest path is also the correct one.

What a reorder portal needs to do (plain requirements)

A wholesale reorder portal should feel personal the moment a buyer signs in. They should only see items they can actually buy, with the pricing and terms that apply to their account. If they manage multiple branches or ship-to locations, the portal needs to respect that context too (different addresses, taxes, allowed products, or contract prices).

At a minimum, buyers need quick access to:

- Their catalog (including any restricted items they are allowed to purchase)

- Their customer-specific prices

- Their order history with clear statuses

If a buyer can’t answer “what did we buy last time?” in seconds, they’ll fall back to email, spreadsheets, or calling support.

The signature feature is a reorder last order button, but it can’t be truly one-click if it creates surprises. A practical “one-click” flow looks like this: click reorder, get a short review screen, then confirm. The review should flag changes that matter, like out-of-stock lines, discontinued items, new minimums, price updates, or shipping limits.

It also helps to separate “repeat what I bought” from “repeat what I usually buy.” Reorder last order works for routine restocks. Saved carts and templates work better for seasonal mixes or standard replenishment packs that don’t match the last invoice.

Assume buyers are teams, not single people. Even a simple portal benefits from basic roles, so people don’t share logins or work around the system:

- Owner/admin: manages users, ship-to locations, and payment settings

- Purchaser: builds carts, places orders, and repeats past orders

- Approver: reviews and approves orders over a threshold

- Viewer: checks pricing, availability, and order status

Data you must store to support customer-specific pricing

A reorder portal only feels “one-click” when the system already knows who is buying, where it ships, and what pricing rules apply. If any of that lives in emails or spreadsheets, reorders turn into back-and-forth.

Start by separating customer identity from shipping identity. Many buyers have one account but multiple ship-to locations, each with its own tax rules, freight terms, or allowed products. Contacts matter too, because the person placing orders isn’t always the person approving them.

Most teams end up needing a small set of core data objects to make pricing reliable:

- Customer account, contacts, and ship-to locations (with active/inactive status)

- Product catalog with variants (size, color, grade), packaging units (case, pallet), and MOQ rules

- Price lists assigned per customer, group, or contract

- Price list lines (product or category), with currency, unit of measure, and quantity breaks

- Validity rules: effective dates, promo windows, and end-of-life/discontinued flags

Pricing rules need dates. Without effective start and end dates, a buyer can reorder an old basket and expect a price your sales team no longer honors.

Also store what the buyer actually saw at checkout. The simplest pattern is an order snapshot: item, unit, quantity, unit price, discounts, and a reason code or source (for example, “Contract C-104, valid through March 31”). When a product is discontinued or a promo expires, you can explain the difference without issuing credits later.

How one-click reorder should work without causing surprises

A one-click reorder sounds simple, but wholesale gets tricky when anything changed since the last purchase. The safest approach is to treat the last submitted order as an immutable snapshot. That snapshot is the receipt: what the buyer agreed to, with the exact items, pricing, and terms at the time.

When a buyer taps “reorder last order,” don’t reopen the old order. Create a new draft order by copying the details buyers expect to stay the same: line items, quantities, ship-to address, delivery instructions, and buyer notes.

Then re-check the new draft before the buyer can place it. This is where most surprises are prevented. A good system verifies the current rules and shows what changed, instead of silently swapping things.

A solid reorder draft check usually includes:

- Recalculate price using the customer’s current price list and contract rules

- Confirm stock and backorder status for each item

- Enforce minimums, maximums, and case-pack rules

- Validate lead times and delivery windows for the selected ship-to

- Re-check discontinued items and restricted products

If something changed, pick one policy and apply it consistently. For small changes (like a minor price update), show a clear warning and let the buyer confirm. For bigger issues (discontinued SKUs, restricted items, minimum not met), block checkout and explain exactly what needs to be fixed.

Substitutions should never happen automatically. If you allow them, present the suggested replacement as an option with a reason (for example, “old size discontinued”) and require explicit approval.

Step-by-step: build your reorder flow from scratch

Start by documenting how reorders happen today. Don’t guess, watch it: a buyer emails “same as last time,” someone searches a spreadsheet, pricing gets checked, and a rep rebuilds the cart. Note every handoff and every place where someone retypes data.

Next, translate pricing into rules you can explain in one sentence. For example: “Retailers in Group A get Price List A, distributors get Price List B, and VIP accounts get 5% off list.” If you can’t say it simply, it will be hard to automate without surprises.

Then design screens around the buyer’s quickest path. Most wholesale buyers only need a few pages: login (and an account or location selector if needed), a catalog with their prices applied, order history with statuses, order details with a clear Reorder action, and a cart/checkout that shows delivery and payment terms.

Before you build, define guardrails that stop bad orders early. Common validations include MOQ and case packs, out-of-stock and discontinued handling, credit hold rules and payment terms, cutoff times for shipping, and address/tax rules per account.

Build a small working version and test it with 2 to 3 real buyers. Ask them to reorder on a call while you watch. Track where they pause, what they expect to be clickable, and what questions they ask.

Roll out in phases and keep a fallback path for exceptions, like a “request help” option or rep-assisted checkout.

UI patterns that make reordering actually faster

Speed comes from fewer decisions. A good portal helps buyers find the right past order in seconds, confirm the key numbers, and place it with minimal typing.

Start with an order history list that works like a good inbox. Search by order number, filter by date range and status, and (if the buyer has multiple branches) make the location or ship-to filter obvious.

On the order detail page, make the “what will I pay?” summary hard to miss. Put subtotal, customer pricing, taxes, shipping, and payment terms in one block, then list line items below. Buyers shouldn’t have to scroll just to learn freight changed or tax was added.

Place the reorder action where the eye already is: top-right on desktop, and sticky at the bottom on mobile. Use confirmation text that explains what happens, not just “Success.” For example: “Reorder creates a new draft using today’s availability and your current pricing. Review before submitting.”

Let buyers edit quantities before final submit, but be explicit about consequences. If quantity changes can affect tier pricing or freight, show a warning next to the line item, not as a surprise at checkout.

Mobile matters because many buyers reorder from a warehouse floor. Keep it thumb-friendly: a sticky bottom action bar, large quantity steppers (not tiny input fields), and short labels in a clean one-column layout.

Common traps that cause credits, returns, and support tickets

Most reorder problems aren’t about the button. They happen when the buyer expects “same as last time,” but the system quietly changes something.

The biggest trigger for credits is showing a price that’s no longer valid, then changing it at checkout or on the invoice. If you support customer-specific price lists, make the price source obvious: contract price, promo, or standard. Better still, re-validate pricing right before the order is placed and clearly message any changes.

Discontinued or substituted items cause returns when the reorder repeats the same SKUs without warning. Don’t block the entire order. Flag the affected line, suggest a replacement if you have one, and let the buyer remove or replace it before confirming.

Internal teams also get stuck when there’s no audit trail. When someone calls to say “you shipped the wrong thing,” you need clear answers: who clicked reorder, when, from which account, and what changed from the previous order (quantity, ship-to, price).

A few practical patterns prevent most tickets:

- Confirm the ship-to every time for multi-location buyers

- Show a short “changes since last order” summary before placing the order

- Make backorders and partial fulfillment a choice, not a surprise

- Ensure final totals match the same calculation used for invoicing

- Log key actions (reorder, edits, approvals) with timestamps and user names

Quick checklist before you launch to real customers

Before you invite real accounts, test the portal like a picky buyer and like your support team. Most failures aren’t “bugs.” They’re surprises: a price that changed, a product that shouldn’t be visible, or a reorder that skips a rule sales normally catches.

Test with at least two customer accounts (one with special pricing and restricted products, one standard). Use a real past order and reorder it.

- Visibility is correct: each buyer sees the right catalog, customer-specific prices, and units (case vs each). Confirm how out-of-stock and discontinued items behave.

- Reorder is fast but not blind: the buyer can review the cart, see price updates and backorders, and confirm before submitting.

- Terms are consistent: the same rules and wording appear on the reorder screen, cart, and final confirmation.

- Validations match reality: MOQ, case packs, max quantities, cutoff times, and delivery windows. Error messages tell the buyer what to change.

- Snapshots are recoverable: you can pull what the buyer saw, which price was used, timestamps, and who submitted.

Example scenario: a buyer reorders in under a minute

Maria buys for a regional cafe chain with two ship-to locations: Downtown and Airport. Each location has its own contract pricing, and a few items are allowed only for Airport due to storage space and delivery windows.

On Monday morning, Maria opens the wholesale reorder portal and taps “Reorder last order.” The portal prompts her to pick a location. She selects Airport.

The portal rebuilds her last Airport cart in seconds. Every line item uses today’s customer-specific price list automatically. Next to each line, she sees available stock and an estimated ship date.

One item from the last order (a 5 lb bag of espresso beans) is now out of stock. Instead of adding it silently, the portal flags the line and asks her to choose: swap to a replacement product with a suggested quantity, backorder it with the earliest ship date, or remove it.

Maria chooses the replacement and accepts the suggested quantity change. Before submitting, she sees a clear summary: ship-to, delivery notes, line items, and the updated total. She confirms.

After submission, internal teams get what they need without extra steps: sales sees the contract pricing used and the substitution decision, the warehouse gets a clean pick list plus backorder/substitution notes, and support has an audit trail showing what changed and who approved it.

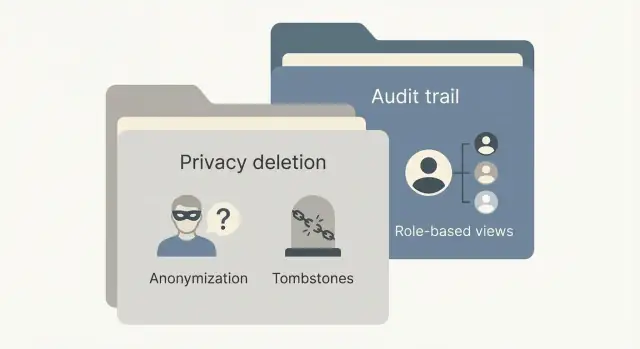

Security, permissions, and audit trail (keep it simple)

A reorder portal is only useful if buyers can reorder quickly without seeing other customers’ pricing or placing orders they didn’t mean to place. You don’t need security theater. You need a few basics done well.

Start with strong login and clear roles. Separate “buyer” (creates carts and submits orders) from “approver” (confirms large orders or contract items). Keep staff/admin roles isolated from customer accounts.

Data separation matters more than fancy features. Every query and screen should be scoped to the customer account and, when needed, to the buyer’s location or branch.

What to log (so disputes are easy)

When something goes wrong, you want facts, not guesses. Log what helps resolve pricing questions and “I didn’t order that” claims:

- Price and discount used at checkout (not just today’s price)

- Product SKU, quantity, and pack size the buyer confirmed

- Who clicked reorder, who edited the cart, and who submitted

- Any approval step (who approved, when, and what changed)

- Address and payment/shipping method selected

If a contract price expires, treat it like a visible rule. Store contract terms with start/end dates, validate them during reorder, and show the new price before submission.

Reduce fraud and accidental big orders

A few small guardrails prevent most bad orders: approval (or re-auth) over a set limit, warnings for unusual quantity jumps, locked fields for contract-only items (no manual price edits), sensible rate limits on reorder actions, and a clear “Review and submit” step even for one-click reorders.

Next steps: start small, then scale the portal

A wholesale reorder portal becomes valuable quickly, but only if the first release is simple and predictable. Start with a small pilot, watch real orders move through the system, then expand once the basics are proven.

Pick one customer group that already orders frequently. Limit the catalog to a tight set of SKUs with stable pricing. That keeps availability, packaging details, and price rules easier to verify.

A practical pilot plan looks like this:

- Launch to 5 to 20 repeat buyers in one segment

- Start with your top 20 to 100 products, not the full catalog

- Support reorder last order plus basic edits (change quantity, remove a line)

- Run the pilot for 2 to 4 weeks before adding features

- Hold a weekly review with sales and support to collect issues

Track a few metrics that reveal whether reordering is actually faster and safer: time to reorder (login to confirmation), error rate (pricing disputes, pack-size mistakes, substitutions), support volume tied to reorders, and abandoned reorders.

Once the pilot is stable, add improvements that match how customers buy: saved templates for “usual” carts, approvals for thresholds, and notifications when something changes after the last order.

If you want to build and iterate without heavy coding, AppMaster (appmaster.io) is one option for creating the portal UI, backend, and workflow rules in one place, then adjusting the flow as you learn from real buyer behavior.

FAQ

Because the “order” is often scattered across emails, PDFs, and spreadsheets. Someone has to retype SKUs, quantities, and terms, then confirm pricing and availability, which adds delays and creates easy-to-miss mistakes.

A reorder portal gives buyers their own catalog, prices, and order history in one place, tied to their account. Instead of rebuilding an order from scratch, they can repeat a past purchase with a quick review and submit it without back-and-forth.

Not if it’s done safely. The best “one-click” flow creates a new draft from the last order, then shows a short review that flags changes like price updates, stock issues, minimums, or discontinued items before the buyer confirms.

At minimum: the buyer’s allowed catalog, their customer-specific prices, and their order history with clear statuses. If any of those are missing or slow to use, buyers will fall back to emailing a rep to avoid surprises.

Separate the customer account from ship-to locations, and store contacts and roles. Many buyers have one account with multiple locations that differ by tax rules, freight terms, allowed products, or contract pricing, and the portal needs to apply the right context every time.

You need price lists (or contracts) that can be assigned by customer or customer group, with line-level rules and effective dates. When the buyer checks out, also store an order snapshot of what they saw—items, units, quantities, unit prices, discounts, and the price source—so disputes are easy to resolve.

Treat the past order as a read-only receipt, then copy it into a new draft order. Before submitting, re-validate current pricing, availability, pack sizes, minimums, and ship-to rules, and clearly show any differences so the buyer isn’t surprised later.

Never swap items silently. Flag the affected line and require an explicit choice, such as removing it, backordering it (if allowed), or selecting an approved replacement with a clear reason, so the buyer stays in control.

Use simple roles so teams don’t share logins: people who build carts, people who approve large orders, and people who only view status and pricing. Also log key actions—who reordered, who edited, who approved, and what changed—so you can quickly answer “what happened?” if there’s a dispute.

You can build the portal UI, backend, database, and workflow rules in one place, then adjust validations and screens as you learn from real buyer behavior. AppMaster is a no-code option that generates production-ready apps and can help you iterate fast without rewriting everything when requirements change.