Cycle Count App: Build a Simple Workflow for Accurate Inventory

Build a cycle count app workflow to create count batches, capture variances, route large deltas for supervisor approval, and post stock adjustments cleanly.

What breaks inventory accuracy in day-to-day work

Inventory usually starts right on day one, then drifts a little every day. Most of the time it isn’t one big mistake. It’s lots of small, normal events that get handled slightly differently each time.

Picking is a common source. A picker grabs the right item from the wrong bin, short-picks with the plan to come back, or scans a label printed for a different case. Returns add more drift: items come back opened, missing parts, or get dropped into a random location “for now” and then forgotten. Damages and shrink do it too, especially when people toss broken items without logging it because it feels faster.

Mislabels are the silent killer. One bad label can create dozens of “mystery variances” later.

Cycle counting is the small, frequent version of inventory checking. Instead of shutting everything down once or twice a year for a full physical inventory, you count a limited set of items or locations on a schedule. The goal is to catch problems early, while they’re still easy to explain.

“Good accuracy” isn’t a perfect number on a report. It means daily work stays predictable: orders ship without last-minute substitutions, purchasing doesn’t over-order “just in case,” and customer support isn’t apologizing for stockouts that shouldn’t exist.

Teams usually struggle for the same reasons. Counts are inconsistent (different units, damaged items skipped). Variances have no clear owner, so people “fix” them by guessing. Large changes get posted without review, so one error becomes a real adjustment. And adjustments aren’t explained (no reason code, no notes, no audit trail), so the same problems repeat.

A cycle count app works best when it makes the right steps hard to skip, and the risky steps impossible to do quietly.

The basic cycle count workflow (in plain language)

A cycle count workflow is a repeatable way to check a small slice of inventory, fix what’s wrong, and keep a record of what happened. A good cycle count app turns that into a simple path people can follow without guessing.

Most teams use the same core flow: plan a count batch, count on the floor, compare to the system, approve exceptions, then post stock adjustments.

Keep roles clear:

- Counter: scans and enters what’s physically there.

- Supervisor: reviews exceptions and confirms the count makes sense.

- Inventory manager: sets the rules (what needs approval, what gets recounted, how adjustments are posted).

Two terms matter during compare: variance and delta. Variance is the signed difference between what the system expected and what you counted. Delta is the size of that difference.

Example: the system says Bin A has 120 units. The counter finds 95.

- Variance = 95 - 120 = -25

- Delta = 25 units

Approval gates exist because big differences can be real problems or simple mistakes. A mis-scan, the wrong unit of measure, or counting the wrong bin can create a large delta. Requiring review for large deltas helps you avoid posting a bad adjustment that creates a bigger mess than the original error.

Once approved, the adjustment should be posted in a controlled way, with who approved it, when, and why captured in the record.

Data you need before you build the app

Before you build a cycle count app, get clear on what data the workflow must capture. If the basics are missing, people will guess on the floor, and results won’t hold up under review.

Start with the minimum master data: items (SKU, name, unit of measure, active/inactive), locations (warehouse and bin structure, and whether a bin is countable), and the current on-hand quantity per item per location. If you use lots or serials, you also need the lot/serial number, expiration date, and status.

Next, define what a count batch means in your business. A batch is the container that makes a count manageable and trackable. It should include the scope (locations or SKU group), planned dates, assigned counters, and a simple status model such as Draft, In Progress, Submitted, Approved, and Posted.

At the line level (each thing someone counts), capture just enough to explain the math later: item, location, system quantity, counted quantity, and the variance (units and, if helpful, percent).

Finally, include approval data from day one, even if you don’t use it at first. You’ll want a variance threshold (what counts as a “large delta”), reason codes (damage, mis-pick, receiving error), a supervisor decision (approve/reject), and notes.

Example: if Bin A3 shows 24 on hand but the counter records 10, the app should require a reason and route it for review before any stock adjustment posting happens.

Creating count batches that people will actually finish

A cycle count app only works if batches feel doable. If someone opens a batch and sees 120 locations, they’ll rush, skip, or abandon it. Start with batches sized for one person in one shift, with time left to fix obvious issues (missing labels, mixed product, damaged packaging).

Pick what to count using rules that match your pain points, not what looks neat on a report. Common approaches include ABC coverage (A items more often, C less), fast movers, repeat-problem bins, and a small amount of randomness to catch quiet drift.

Keep each batch tight: a single zone, a single aisle range, or a cluster of nearby bins. If travel time is high, the batch is too wide. A practical starting point is 20 to 40 locations per batch for a manual count, then adjust based on how long your team actually takes.

Decide how you’ll handle movement during counts. The cleanest option is to block picks and putaways for bins inside an active batch. If you can’t block movement, use a timestamp cutoff: anything after the cutoff is excluded and handled in a follow-up.

Clear statuses prevent confusion and reduce rework. Use names that match what people do:

- Draft

- In progress

- Submitted

- Approved

- Posted

If you’re building this in AppMaster, you can model batches, locations, and statuses in the Data Designer, then add rules in the Business Process Editor so the app blocks edits once a batch is Posted.

Recording counts on the floor without slowing people down

The fastest counts happen when the screen matches what a person is doing with their hands. That usually means one simple entry view that works in a noisy aisle, with gloves, glare, and bad Wi-Fi.

Limit inputs to what a counter can truly confirm: item, bin (or location), counted quantity, and an optional note. If photos help resolve disputes later, make them optional and one-tap. Anything that feels like paperwork will get skipped, or worse, guessed.

Make scanning available, but not required. Barcode scans are great when labels are clean, but you still need a manual fallback for torn labels, dead scanners, or mixed packaging. A solid pattern is: scan item (or search), confirm bin, enter quantity.

Show the system quantity, but keep it read-only. Counters shouldn’t be able to “fix” the number on the spot. Seeing the expected quantity can help them double-check obvious mistakes, but it shouldn’t overwrite what they physically counted.

Two cases confuse people and deserve explicit handling:

- Not found: the location is empty or the item is missing at that bin.

- Found extra: the item exists in a bin where the system says it shouldn’t.

In both cases, still capture the bin and the count (even if it’s zero). That keeps the record usable for review and adjustments.

If you build this in AppMaster, you can keep the entry screen minimal with a mobile UI, use scanner input when available, and store photos and notes alongside each count line so supervisors can review without chasing people down.

Capturing variances and setting “large delta” rules

A cycle count app is only as trustworthy as its variance rules. The moment someone can “fix” a bad count by editing a number, the process stops being a control and turns into a suggestion.

Use simple math on every line item:

- Variance (units) = counted quantity - system quantity

- Variance (%) = (variance units / system quantity) x 100

Percent difference helps you spot big problems on small-stock items. Unit difference helps you spot costly swings on high-volume items. If the system quantity is 0, treat it as a special case and route it to review automatically.

Defining what counts as a “large delta”

Use thresholds that match how your operation behaves. Many teams combine absolute units and percent so neither small items nor fast movers slip through.

For example:

- 10+ units OR 5% for everyday SKUs

- 2+ units OR 20% for high-value parts

- Any count where system quantity is 0

- Any adjustment that would create a negative on-hand

Keep the rule easy to explain. People accept controls when they understand them.

Next, require a reason code whenever variance isn’t zero. This forces a quick “why” while the item is still in front of the counter, and it makes reporting useful later. Typical reason codes include damaged/expired, mis-pick/short ship, relocated (bin change), receiving not posted, and label or unit-of-measure issues.

Finally, prevent risky edits. Once a counter submits a batch (or a line) for review, lock it. If something truly needs correction, make it a supervised recount that creates a new entry and keeps the original intact. That one rule protects your audit trail and stops quiet changes after the fact.

Supervisor review that is fast and auditable

Supervisor review should take minutes, not hours. The trick is to show the decision-maker the context they need on one screen and keep the actions simple.

Supervisors rarely need only the raw count. They need the item’s recent story: prior cycle counts, the expected on-hand, and what changed since the last clean count (receipts, picks, returns, transfers). When your cycle count app can show that timeline next to the variance, supervisors stop guessing.

What the supervisor screen should include

Keep it practical:

- Item and location details (SKU, bin, lot/serial if used)

- Expected vs counted, plus delta in units and percent

- Last 2-3 counts for that item/location

- Recent stock movements since the batch started

- Notes and photos from the counter (if you allow them)

Actions should match real life: approve when it’s clear, reject when the count is invalid, request a recount when the floor conditions look messy, and split the batch when only a few lines are questionable so the rest can move forward.

For large deltas, require a comment before approval. Keep the prompt specific (damage found, mis-pick confirmed, unposted receipt, unit-of-measure issue).

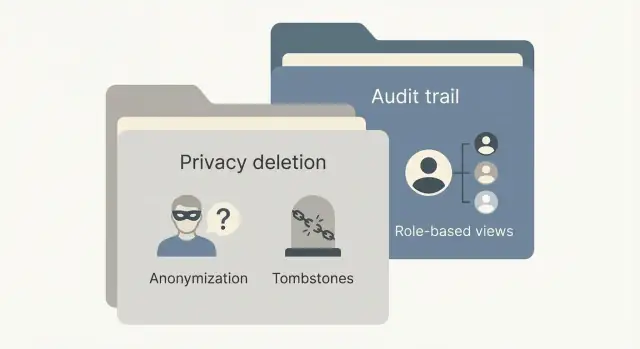

Make the audit trail automatic

Every decision should write: who decided, when, what action, the threshold that triggered review, and the reason text. If you build this in AppMaster, capture these fields as part of the approval step so the record is created every time, without relying on memory.

Posting approved stock adjustments safely

Posting is the moment your numbers change. It means updating on-hand quantities and saving a permanent record of what changed, when, and why.

Keep approval and posting as two separate steps. Approval is a decision. Posting is a write to inventory. If you mix them, a mis-tap or a half-finished review can change stock before anyone notices.

A simple rule for a cycle count app: only approved variances can generate adjustments, and only adjustments can update on-hand.

Create an adjustment record per item and location (one line per SKU and bin), even if you post a whole batch at once. Each line should carry the same references so you can audit later: count batch ID, item, location/bin, system quantity, counted quantity, delta, reason code, approved by, approved at, and who posted it.

Before you let a user post, add a few safety checks:

- Confirm the batch is locked (no more edits to counts)

- Recalculate totals and confirm nothing changed since approval

- Prevent double posting with a unique posted flag and timestamp

- Require a posting role (separate from counter)

- Keep an undo path (a reversing adjustment, not deletion)

Posting should be explicit on the screen. Show a final summary of how many lines will change and the total delta, so the user knows exactly what will happen.

Plan for integrations early, even if you don’t build them on day one. If your ERP or WMS is the source of truth, treat posting as “export approved adjustments” and let the other system apply them. In AppMaster, you can model adjustments as a table and later add an export to CSV or an API call without changing the counting workflow.

Example scenario: a large variance that needs approval

A picker starts a cycle count for Bin A-14 (Item: 10mm bolts). The system shows an expected quantity of 50, based on the last received shipment and recent picks. On the floor, the picker counts 43.

That 7-unit gap can happen for simple reasons: a box was moved to a nearby bin during a rush, a pick was done but not confirmed, a return was put back without a transaction, or the bin label is worn and someone stocked the wrong location.

In the cycle count app, the picker taps Submit Count. The app calculates the delta (-7, or -14%). Since the warehouse rule says anything over 10% needs approval, it doesn’t allow an adjustment to post yet. Instead, it routes the count into a Needs Review status and asks for a quick recount.

On the recount, the picker finds a small unopened carton behind a larger one and updates the recount to 45. The variance is now -5 (still -10%). The app keeps it in review and prompts for a short note like “Found hidden carton, recount completed.”

The supervisor opens the review queue and sees the original count, the recount, timestamps, and who counted. They choose an action:

- Approve the adjustment to 45 and add a root-cause note (for example, “Storage layout blocked visibility”).

- Reject and request a second recount if the bin is messy or the item is high-risk.

- Pause and trigger a quick check of nearby bins if mis-slotting is likely.

Once approved, the app posts a stock adjustment from 50 to 45 with an audit trail. The team also records the learning: rearrange the bin to prevent hidden cartons and add a reminder to confirm picks before leaving the aisle.

Common mistakes that make cycle counts unreliable

Most cycle count problems aren’t about effort. They come from small workflow gaps that quietly turn your numbers into guesswork.

One of the biggest mistakes is letting people overwrite the system quantity. It feels quick, but it destroys the audit trail. A count should create a variance, then create a stock adjustment that is reviewed and posted. That way you can always see what changed, when, and why.

Another common issue is counting a moving target. If picking, receiving, or transfers keep happening while someone is counting a bin, your variance becomes meaningless. Even a simple cutoff helps, like pausing movements for a location while a batch is in progress, or requiring a recount if a movement happened during the count window.

Batch size matters more than most teams expect. If batches are too large, they spill across shifts, people lose context, and the batch never closes. Smaller batches create a faster rhythm and cleaner data.

A few failure patterns show up again and again: missing reason codes for variances, approvals done in chat with no record, unclear units (each vs case), fixing items one by one instead of using a consistent count batch workflow, and allowing “quick edits” that bypass stock adjustment posting.

A quick example: a counter finds 12 units in a bin that the system says has 20. If there’s no reason code, you can’t tell later if it was theft, damage, a pick error, or a receiving mistake. If supervisor approval happens in a message thread, you also can’t prove who accepted the risk.

A good cycle count app prevents these errors by design: locked system quantities, required reason codes, and an approval step that’s recorded before any stock adjustment is posted.

Quick checklist before you roll it out

Before the first real count, do a dry run with one aisle or one small stockroom. You’re not testing people, you’re testing the process.

Make sure:

- The batch scope is obvious: batch name, locations or SKU range, count date, and assigned counter.

- Counting still works when the signal is bad: offline is ideal, but a clear fallback is fine (cached task list plus later sync, or a short paper form that gets entered the same day).

- Variance thresholds are agreed and tested: define what counts as a large delta (percent, units, or value) and test with low-stock and high-value items.

- Supervisor review is required and time-boxed: large deltas should route to a reviewer with a clear deadline so batches don’t sit open for days.

- Posting is safe and traceable: approved adjustments create an audit record (who counted, who approved, what changed) and then the batch locks.

If you’re building this in AppMaster, set these as simple rules in your Business Process: validate scope, enforce thresholds, require approval, then post and lock.

Next steps: pilot, improve, and build the app your team needs

Start small so you can learn fast. Pick one warehouse zone, one product family, and a short reason-code list (damage, mis-pick, shrink, receipt not posted). A narrow pilot makes it easier to spot where the workflow is confusing, where counts take too long, and which variance rules trigger too often.

Run the pilot for a week, then tighten the workflow based on what actually happened on the floor. Keep the goal simple: finish batches on time, and make variances easy to explain and approve.

A practical first-week plan:

- Pilot one zone with a daily batch size people can finish

- Review the top variances and confirm your reason codes cover them

- Tune your variance approval thresholds so supervisors only see what matters

- Decide when a recount is required vs when approval is enough

- Publish a one-page cheat sheet: how to count, when to pause, what to do on exceptions

Once the basics work, choose what to automate next. Most teams get quick wins from a few additions: notifications when a batch is assigned or overdue, automatic routing to recount when a large delta hits, and a daily report that shows completion rate, repeat-variance SKUs, and pending approvals.

If you want to build a cycle count app without heavy coding, AppMaster (appmaster.io) is one option: you can model your inventory data, set up variance approval steps, and generate both web and mobile apps from the same workflow.

FAQ

Cycle counting checks a small set of items or bins on a regular schedule instead of doing one big annual physical count. The main benefit is catching drift early, while the causes are still fresh and easy to fix.

Start with a size one person can finish in one shift without rushing. For many warehouses, 20–40 locations per batch is a practical first target, then adjust based on real timing and travel distance.

Block picks and putaways for bins in an active batch whenever you can, because it keeps the count from becoming a moving target. If you can’t block movement, use a clear cutoff time and require a recount if transactions happened during the count window.

Use scanning when labels are reliable, but always include a manual fallback for torn labels, mixed packaging, or dead scanners. A simple flow that works well is: identify item, confirm bin, enter quantity, then submit.

Keep the system quantity visible but read-only so counters can’t “fix” numbers on the spot. A count should create a variance, and only an approved adjustment should update on-hand quantities.

Start with a combined rule that catches both big unit swings and big percent swings, such as “10+ units or 5%,” then tune it based on how noisy your inventory is. Treat any count where the system quantity is zero as automatic review because it often signals mis-slotting or missing transactions.

Use a short list that matches real root causes, like damage/expiry, mis-pick/short ship, receiving not posted, relocation, and label or unit-of-measure issue. Keep it consistent so reports show patterns instead of a pile of one-off explanations.

Let supervisors approve, reject, or request a recount, and require a short note for large deltas so the decision is explainable later. The review screen should give enough context to avoid guessing, like recent counts and recent movements for that item and location.

Keep approval and posting as separate steps, and only allow posting for approved lines. Posting should create a permanent adjustment record (who counted, who approved, what changed, and why) and prevent double-posting with a posted flag and timestamp.

Yes, if it enforces the workflow instead of relying on memory, especially locking submitted counts, requiring reason codes, and recording approvals automatically. In AppMaster, you can model batches and count lines, add approval rules in a Business Process, and generate web and mobile apps from the same workflow.